Operador de Máquina CNC: O Que Faz? The Core of Modern Manufacturing Precision

Operador de Máquina CNC: O Que Faz? The Core of Modern Manufacturing Precision

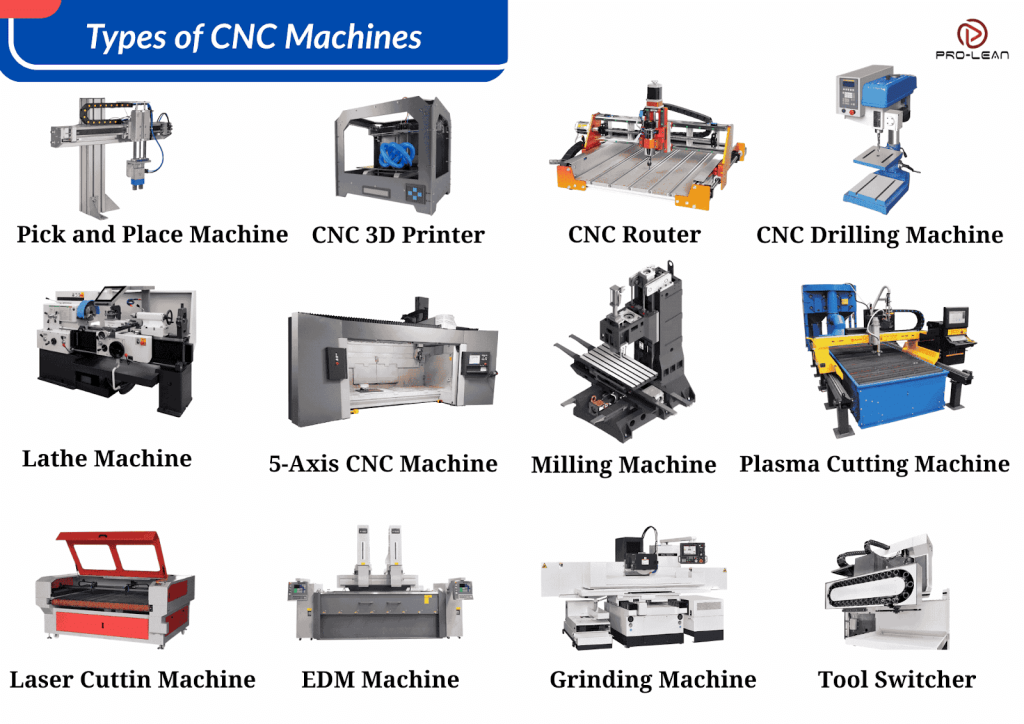

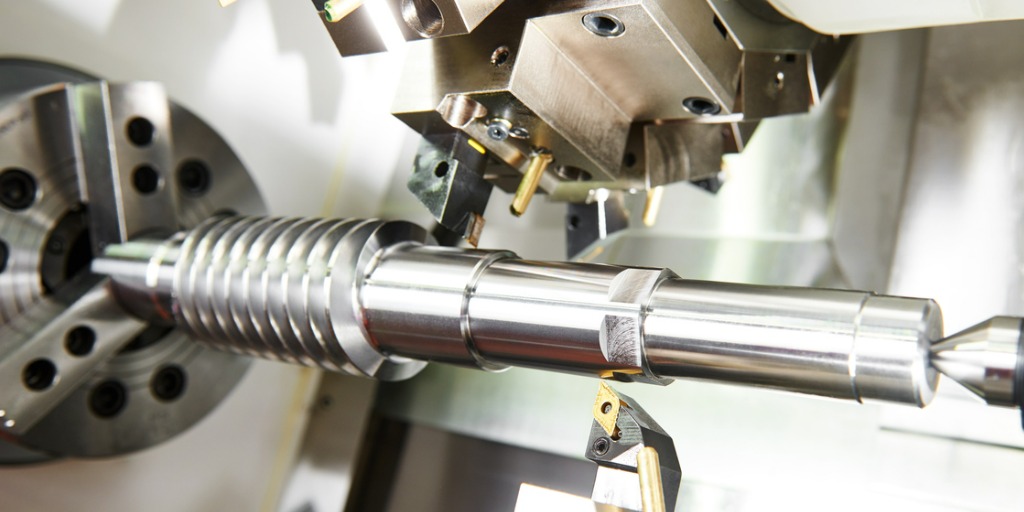

At the heart of automated industrial production lies the Operador de Máquina CNC — the skilled operator who transforms raw material into engineered components with surgical accuracy. Far more than a technician, the CNC operator manages complex machines programmed through computer numerical control, ensuring that every cut, drill, and movement aligns perfectly with digital blueprints. This role merges technical expertise with real-time decision-making, making it indispensable in manufacturing across automotive, aerospace, electronics, and custom fabrication sectors.

But what exactly does an operator do, and why is this function so critical in today’s high-precision fabrication landscape?

Mastering the Machinery: Core Responsibilities of a CNC Operator

Operating a CNC machine requires a deep understanding of both its mechanical systems and software underpinnings. The operator’s primary duty is to interpret digital CNC programs—written in G-code or similar languages—and load them into the machine’s control system.Using this, they initiate cycles to machine parts according to strict design specifications. Every step is defined by precision: - Loading workpieces with correct positioning and secure fixation to prevent movement during cutting. - Setting machine parameters such as spindle speed, feed rate, and depth of cut—variables that determine precision and material integrity.

- Managing tool changes, ensuring correct tool selection and installation before each operation. - Monitoring machine behavior throughout the process, detecting anomalies such as unusual vibrations, noise, or deviations from expected motion patterns. - Performing pre- and post-run inspections, verifying dimensions using calipers, gauges, or coordinate measuring machines (CMMs) to confirm compliance.

“An operator is the bridge between digital design and physical part,” states veteran CNC technician Rafael M. In a 2023 manufacturing survey. “Without their vigilance, even the most advanced CNC system cannot guarantee quality output.”

Operators also adapt dynamically—adjusting settings mid-run when tolerances drift or materials behave unexpectedly.

Their knowledge extends beyond programming and mechanics to include safety protocols, machine maintenance basics, and troubleshooting minor malfunctions.

Skills and Expertise: What It Takes to Be a Successful CNC Operator

Success in operating CNC machinery demands a unique blend of technical and cognitive abilities. While formal education in mechanical engineering or manufacturing technology often provides foundational knowledge, practical proficiency is refined through hands-on experience. Core competencies include: - Fluency in reading and interpreting technical blueprints, tolerances, and CAD-derived toolpath data.- Proficiency with CNC programmers, often using software like Mastercam, SolidCAM, or G-Wizard. - Problem-solving skills to diagnose and resolve machine errors, spindle issues, or tool wear. - Attention to detail in setup and inspection, minimizing scrap and rework.

- Physical stamina and hand-eye coordination, as operators frequently interface directly with machinery. Modern operators must also adapt to evolving technologies—integrating IoT-enabled monitoring systems, robotic material feeders, and automated tool changers that expand traditional operational scopes. Continuous learning through manufacturer certifications, on-the-job training, and digital learning platforms ensures sustained performance in rapidly advancing technical environments.

While entry-level roles focus on machine operation, experienced technicians evolve into technical leaders, guiding new operators, optimizing workflows, and contributing to process innovation—highlighting the depth of expertise embedded in the CNC operator’s role.

Operational Impact: How CNC Operators Drive Efficiency and Quality

The role of a CNC operator directly influences a facility’s competitiveness. By maintaining strict adherence to operational parameters, the operator ensures manufacturing consistency across thousands of parts, minimizing waste and reducing production downtime. Critical contributions include: - Sustaining tight tolerances—often within microns—essential for assembly integrity in industries like aerospace and medical devices.- Enabling high-precision, repeatable production runs that reduce reliance on manual labor and human error. - Acting as early detectors of equipment drift or calibration issues, preventing costly cycle failures. - Supporting lean manufacturing goals through optimized material usage and reduced scrap rates.

“Every part that leaves CNC production lines carries the fingerprint of the operator’s precision,” explains Dr. Elena Torres, a manufacturing systems expert. “Their role is not just operational—it’s foundational to delivering value.” In environments where production spans multiple materials—metals, polymers, composites—operators tailor machine settings swiftly, balancing tool life, cutting speeds, and surface finish.

This agility supports just-in-time manufacturing and responsive client demands, reinforcing CNC operators as linchpins of modern industrial supply chains.

Furthermore, CNC operators frequently collaborate with engineers and quality assurance teams, feeding real-time feedback on machine performance into design refinement cycles. Their frontline insights drive continuous improvement, contributing directly to innovation and process optimization.

The Evolving Role: Bridging Tradition and Innovation in CNC Operations

As automation advances with artificial intelligence, real-time analytics, and cloud connectivity, the CNC operator’s scope continues to

Related Post

Operador de Máquina CNC: O Que Faz—A Tecnologia Por Trás da Precisão Industrial

Operador De Máquina CNC: O Que Faz e Como Transforma Indústria

Operador de Máquina CNC: O Que Faz e Por Que É Indispensável na Manufatura Moderna

From Insecurity to Strength: Vanessa Bryant’s Powerful Journey of Weight Loss and Transformation