Operador de Máquina CNC: O Que Faz e Por Que É Indispensável na Manufatura Moderna

Operador de Máquina CNC: O Que Faz e Por Que É Indispensável na Manufatura Moderna

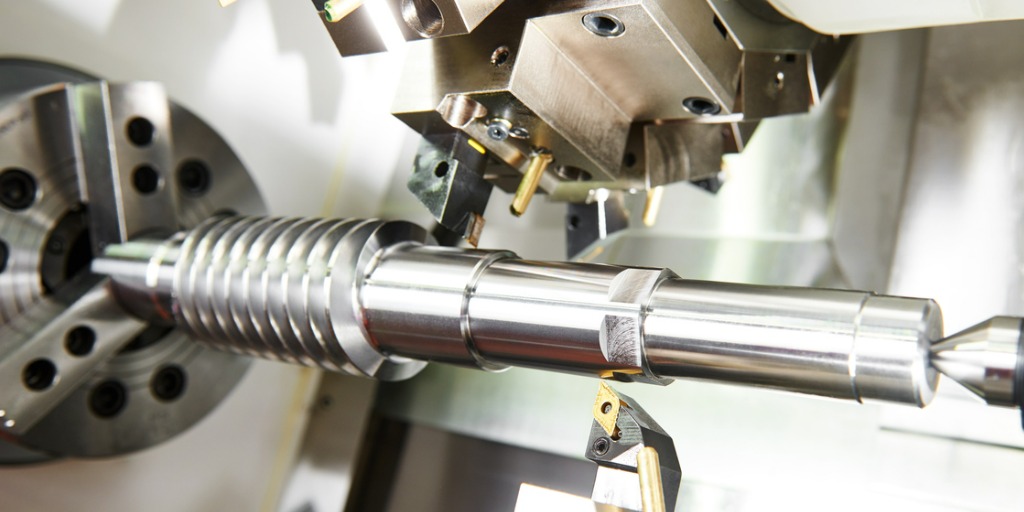

Precision, speed, and consistency define the era of modern manufacturing — and at its core stands the Operador de Máquina CNC, a pivotal figure behind the seamless operation of Computer Numerical Control (CNC) systems. Far more than a machine user, the CNC operator initiates, monitors, and manages automated production processes with technical expertise and vigilant oversight. This article reveals the essential function of the Operador de Máquina CNC—how they shape factory workflows, ensure product integrity, and drive industrial efficiency.

The role of the Operador de Máquina CNC is central to transforming digital design files into tangible, high-accuracy components. “The operator is the human bridge between CAD/CAM software and the physical machine,” explains Dr. Ana Pereira, a mechanical engineering specialist with over a decade of industry experience.

“Without their precise input and continuous monitoring, even the most sophisticated CNC program cannot guarantee quality output.” Operators set up machines by loading raw materials, selecting the correct tooling, and entering programmed instructions—each step calibrated to exact specifications strict enough to meet industrial tolerances often within microns.

At the heart of CNC operation lies real-time supervision, a critical function often underestimated. The operator monitors multiple parameters during machining, including spindle speed, feed rates, tool wear, and potential machine anomalies.

Error detection is paramount: a minor deviation can cascade into defective parts, costly rework, or equipment damage. “A skilled operator doesn’t just press start—they remain actively engaged, analyzing data through control panels, interpreting tool condition signals, and intervening when irregularities arise,” notes Marcelo Ferreira, a CNC technician certified in advanced automation.

Among the core responsibilities is machine calibration—ensuring all axes align perfectly and movements follow prescribed paths.

Precision marines in this phase: even a 0.01 mm misalignment may compromise the final product, especially in aerospace or medical component manufacturing where tolerances are uncompromising. Operators verify calibration daily, using laser interferometers or knives to validate accuracy.

Another key function is tool management.

CNC machines depend on tool changing mechanisms that require constant attention. Operators monitor tool life, switch inserts proactively to prevent breakage, and maintain detailed logs of wear patterns. “Proper tool control extends tool life and maintains surface finish quality,” states Pablo Mendes, a production manager at a Brazilian precision parts factory.

“We track every tool’s usage through digital logs, anticipating replacements before failure occurs.”

Process optimization enhances production efficiency, a responsiveness few non-operators master. Experienced operators adjust feed rates dynamically, respond to material inconsistencies, and fine-tune cycles in response to real-time feedback. This adaptability minimizes downtime and maximizes throughput—critical in competitive markets where time-to-market defines success.

- Set up and program CNC machines using G-code and CAM output data.

- Monitor and control machining parameters in real time.

- Perform and verify tool calibration and alignment checks.

- Manage tool life through scheduled changes and condition monitoring.

- Detect and resolve anomalies, preventing costly errors.

- Maintain detailed logs and documentation for quality and traceability.

The training and expertise required to excel as an Operador de Máquina CNC are substantial. Most professionals train through structured programs combining theoretical knowledge—like machining principles and metrology—with hands-on machine operation. Certifications in CNC programming, safety protocols, and ISO standards validate competence, ensuring operators meet global manufacturing benchmarks.

“Continuous learning is essential,” emphasizes Dr. Pereira. “Technology evolves rapidly, and operators must stay current with software updates, new materials, and automation trends.”

In practical terms, CNC operators enable industries to achieve unprecedented levels of precision and repeatability.

Automotive manufacturers depend on them to produce engine components with micron-level tolerance; electronics firms rely on rapid, accurate fabrication of circuit housings. Aerospace and defense sectors demand faultless production of mission-critical parts, where operator vigilance directly safeguards operational safety.

Operador de Máquina CNC is more than a technical role—it is a cornerstone of modern manufacturing excellence.

Through meticulous setup, vigilant monitoring, and strategic optimization, these operators transform digital commands into flawless physical results. As industrial automation advances, their adaptability and expertise remain irreplaceable, ensuring CNC technology delivers both quality and reliability in an increasingly automated world. The CNC machine doesn’t think—it executes.

The operator, however, ensures every execution counts.

Related Post

Operador de Máquina CNC: O Que Faz—A Tecnologia Por Trás da Precisão Industrial

Operador de Máquina CNC: O Que Faz? The Core of Modern Manufacturing Precision

Operador De Máquina CNC: O Que Faz e Como Transforma Indústria