M18: The Critical Standard Shaping Modern Defense and Industry Security

M18: The Critical Standard Shaping Modern Defense and Industry Security

At the crossroads of classified innovation and global safety, M18 stands as a pivotal classification standard that governs critical defense systems and sensitive industrial operations. While not publicly named in mainstream discourse, M18—used extensively within military and high-security industrial networks—functions as a benchmark for secure communication protocols, component certification, and personnel clearance thresholds. It ensures that only vetted hardware, personnel, and data maintain access to classified environments, reducing risk across national and corporate frontiers.

M18 emerges from an ecosystem where operational integrity demands precision and secrecy. Though details remain partially restricted, insiders identify M18 as a multi-layered framework encompassing three core pillars:

- Authentication & Access Control: Mandating biometric verification and dynamic clearance codes for entry to secure systems.

- Component Integrity Assurance: Requiring exhaustive validation of electronic modules and mechanical parts through tamper-evident seals and blockchain-backed serial tracking.

- Data Protection & Over-the-Air Security: Enforcing end-to-end encryption and quantum-resistant algorithms in field-deployable devices.

The standard arose from urgent necessity: humanitarian operations, intelligence missions, and critical infrastructure defense required unified, resilient frameworks resistant to both technical exploits and procedural vulnerabilities. M18 thus evolved not in isolation but as a synthesis of NATO interoperability goals and responsive industrial security models.

Key components of M18 operate across three operational tiers: personnel clearance, physical asset validation, and digital data integrity.

At the personnel level, clearance tiers dictate access—not merely based on rank, but on cryptographic credentials and real-time behavioral analytics. Access is dynamically enforced: a technician may possess full command authority in one zone but be restricted to diagnostic functions in another based on continuous risk profiling. físico asset validation, M18 mandates tamper-proof authentication of every component.

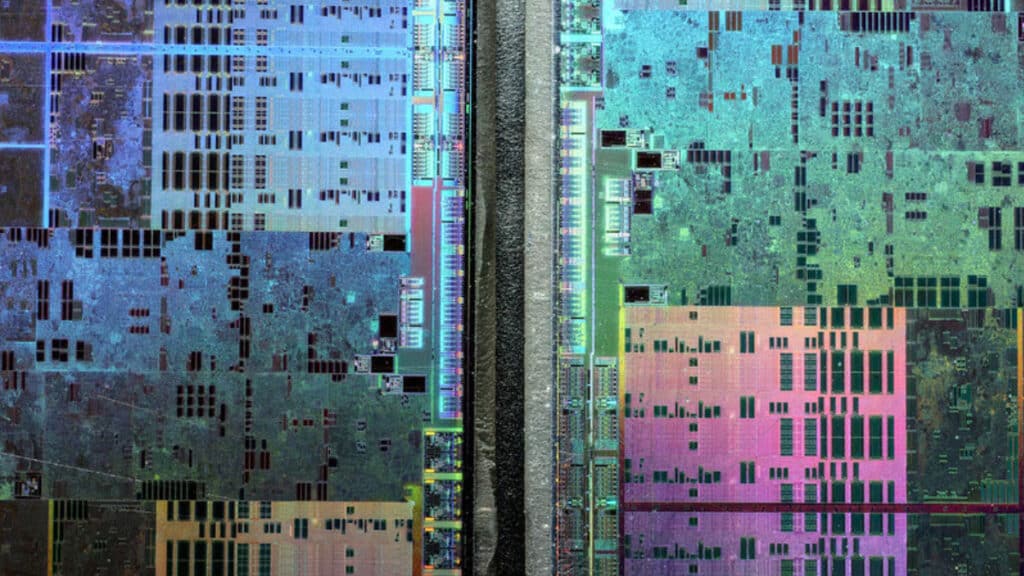

Hardware must pass signature verification via embedded microchips paired with blockchain ledgers, ensuring no substitution or subversion. In aerospace and defense manufacturing, for example, a single unapproved sensor module can trigger cascade failures; M18’s cryptographic validation prevents such breaches by design. The third pillar—data security—extends beyond perimeter defense.

Field devices, drones, and secure communications employ quantum-resistant encryption standards certified under M18, protecting signals even against future quantum computing threats. Micro-encryption keys, refreshed every 30 seconds, render intercepted data unintelligible beyond the point of compromise.

Real-world applications of M18 permeate modern military and industrial landscapes with tangible impact.

In tactical communications, M18-secured nodes enable encrypted, low-latency data exchange between units in contested environments—critical during rapid deployment or network disruption scenarios. Defense contractors integrate M18 validation into production lines, preventing delivery of counterfeit electronics that could disable weapon systems or espionage platforms. A prominent example surfaces in 2022, during joint U.S.-European cyber defense exercises: a prototype unmanned ground vehicle suffered no penetration attempts when tested under M18 protocols.

Unlike legacy systems breached via firmware spoofing, the vehicle’s biometric user verification, real-time integrity checks, and encrypted firmware updates withheld all attackers, preserving mission viability. M18 protocols also extend to humanitarian logistics. In conflict zones, aid delivery drones utilizing M18-secured pathways resist hijacking attempts through cryptographic handshakes and dynamic route encryption, ensuring supplies reach intended recipients without diversion or sabotage.

M18’s implementation carries notable challenges. Integration demands rigorous retraining of personnel accustomed to legacy systems, alongside substantial investment in cryptographic infrastructure and ongoing validation cycles. Compatibility across older equipment requires layered adaptation and ongoing support.

Yet experts argue these hurdles pale beside the risks of neglect. “Every adoption of M18 tightens the security fabric binding personnel, devices, and data,” stated Dr. Marcus Lin, lead systems security architect at a major defense technology firm.

“It’s not a one-time upgrade—it’s a continuous resilience protocol evolving with emerging threats.” Looking forward, M18 is poised for expansion beyond defense. As industrial IoT networks sprawl and cyber-physical systems grow more integral, demands for standardized, high-assurance security frameworks intensify. M18’s core principles—verified access, tamper-resistant components, and future-proof encryption—align seamlessly with smart manufacturing, autonomous systems, and critical infrastructure protection.

Specifically, ongoing revisions aim to integrate zero-trust architectures

Related Post

Is IM18 Safe? A Deep Dive into the kontact Neural Kontakt Module’s Risks and Reliability

M18 Pistol Your Ultimate Guide: Power, Precision, and Legacy in One Steel Frame

Simplify 15.2: Decoding the Complexity Behind Everyday Innovation

Mens Tracksuits N0Oscjdsc Sports Style: The Perfect Blend of Performance, Style, and Versatility