Jordan 13 Flints: The Hidden Edge Forging Mastery in Modern Flint Craftsmanship

Jordan 13 Flints: The Hidden Edge Forging Mastery in Modern Flint Craftsmanship

Pixel-perfect sparks. Precision-ground edges. A legacy redefined.

Jordan 13 Flints represent a category of high-performance flint products that blend traditional craftsmanship with modern engineering, setting a new benchmark for flint flaking in analytical, survivalist, and traditional tool-making communities. These flints are not merely tools—they are precision instruments shaped to deliver consistent, reliable ignition under demanding conditions. Every Jordan 13 Flint is crafted from premium.

High-quality chert or flint nodules, selected for uniform density and fracture morphology. The manufacturing process begins with controlled splitting to shape the blank, followed by meticulous grinding and pressure-knapping techniques that define the striking platform and bevel angle. This工序 ensures optimal edge geometry, enabling controlled spalling and maximum ignition efficiency—critical for applications ranging from archaeological experimentation to survival preparedness.

Performance Meets Precision: Key Engineering Features Central to the Jordan 13 Flint’s reputation is its synergistic balance of raw material integrity and engineered geometry. Fluorite-infused chert, often sourced from specific geological formations, provides superior conchoidal fracturing—the hallmark of reliable spalling. This predictable break pattern ensures flint enthusiasts and professionals alike can anticipate consistent flake yields, a vital advantage in fieldwork and ritual knapping alike.

- **Striking Platform Optimization**: A precisely beveled edge reduces the risk of accidental flake misdirection, preserving material and improving consistency. - **Edge Geometry**: Slightly convex flaking enhances stress concentration at the intended break point, delivering sharper, more durable cutting edges. - **Material Homogeneity**: Advanced sorting ensures homogeneity across batches, minimizing variability from inconsistent nodule quality.

Such design choices reflect decades of empirical refinement, with Jordan 13 Flints standing as a synthesis of ancestral technique and modern material science. Applications Beyond the Ignition Gap While best known for their flint-sparking capability, Jordan 13 Flints transcend this singular function. In the world of experimental archaeology, researchers rely on these flints to replicate prehistoric tool-making processes, testing hypotheses about early human technological behavior.

Their predictable fracture mechanics enable accurate recreations of stone-point arrowheads, scrapers, and cutting tools. Survivalists and bushcrafters prioritize Jordan 13 Flints for their rugged reliability. In wet or damp environments—conditions that typically degrade less stable materials—these flints maintain performance due to their dense mineral structure and optimized edge retention.

Unlike brittle alternatives prone to catastrophic breakage, Jordan 13 Flints reward patience and skill, rewarding the user with consistent results when properly maintained. Craftsmanship as a Differentiator What distinguishes Jordan 13 Flints from mass-produced replicas is the artisanal rigor behind each piece. Masters flintknappers manually inspect raw material before processing, applying forces calibrated not just by instinct but by biomechanical understanding.

Each flake pattern, diameter, and weight is logged to optimize functionality. Custom orders often feature bespoke dimensions or edge shapes, tailored to specific user needs—whether for detailed ethnographic replication or rugged fieldwork. “Every Jordan 13 Flint tells a story—not of arbitrary flaking, but of deliberate, informed design,” notes Dr.

Elena Cho, Senior Archaeological Technologist at the North American Stone Tool Research Initiative. “It’s where material science converges with human ingenuity.” Sustainability also defines the Jordan 13 brand: waste is minimized, and traditional cold-flaking techniques reduce energy use compared to industrial forging. This eco-conscious approach resonates with a growing community invested in heritage practices and environmental stewardship.

The Rise of Jordan 13 Flints in Contemporary Culture Beyond laboratories and wilderness camps, Jordan 13 Flints have entered mainstream enthusiasts’ lives, celebrated in online forums, knapping workshops, and survivalist collectives. Their appearance in instructional videos and gear roundups reflects a wider cultural shift toward hands-on skills and tangible craftsmanship in a digital age. From selling at independent stone tool fairs to being featured in documentaries about ancestral technologies, Jordan 13 Flints serve not only practical purposes but also symbolic ones—bridging past and present through the enduring art of the stone.

In essence, Jordan 13 Flints are more than flints—they are instruments of precision, heritage, and resilience, embodying a perfect union of material mastery and purpose-driven design. Their enduring appeal stems not from flashy marketing but from uncompromising performance grounded in centuries of flintworking wisdom. The Jordan 13 Flints exemplify how advanced understanding of material science and knapping artistry converge to produce tools that ignite more than fire—they ignite tradition, innovation, and the human spirit.

Related Post

Illicit Love: The Hidden Forces Shaping Forbidden Affections

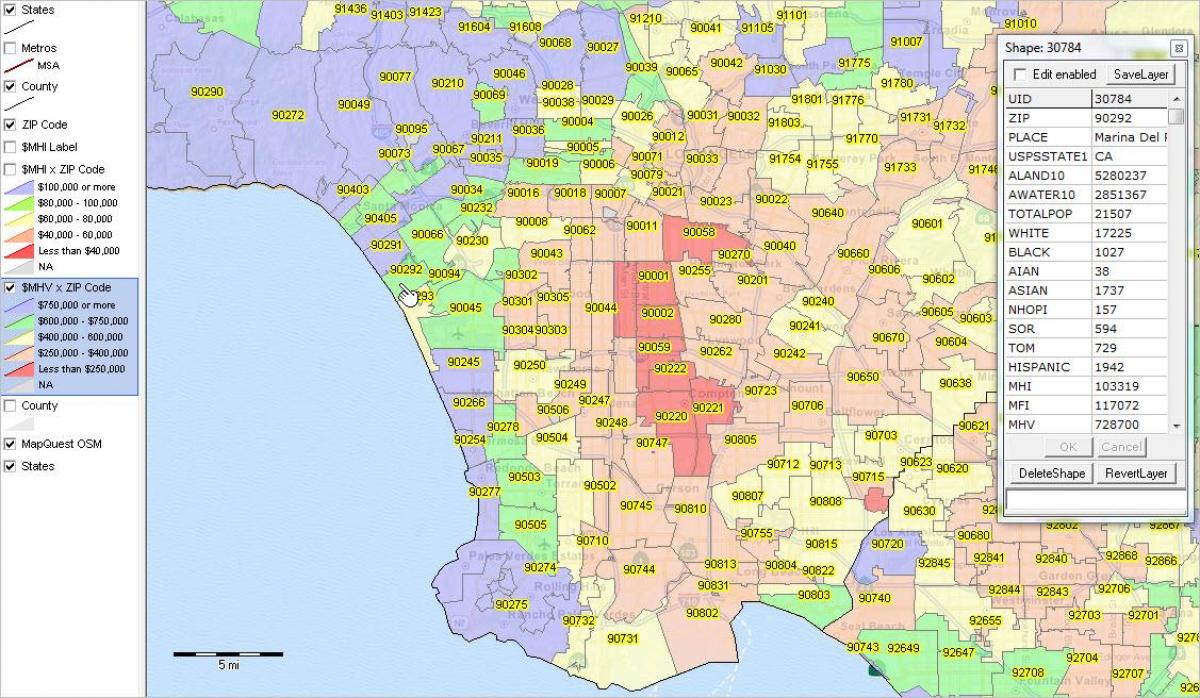

Brentwood Zip Codes: Decoding Los Angeles’ Most Coveted Neighborhoods by Postal Code

Aubrey Wyatt Obituary: Remembering A Life Well-Lived

Revealing the Secret Story of Jack Jeebs: MIB's Quintessential Shady Contact