Freightliner Brake Pressure Switch: Unlocking Precision, Diagnosing Failures, and Repairing Under Pressure

Freightliner Brake Pressure Switch: Unlocking Precision, Diagnosing Failures, and Repairing Under Pressure

For Freightliner heavy-duty truck operators and maintenance technicians, reliable braking performance is non-negotiable—especially on long hauls through challenging terrain. At the core of this safety system lies the brake pressure switch, a critical component that monitors hydraulic integrity and triggers alerts when pressure drops. Understanding its function, diagnosing faults, and executing timely repairs ensures brake systems operate at peak efficiency, safeguarding both cargo and drivers.

When a Freightliner brake pressure switch triggers a warning light or reduces system responsiveness, swift diagnosis and precise repair prevent costly downtime and potential safety risks. This article dissects the mechanics, diagnostic techniques, and step-by-step repair strategies for the Freightliner brake pressure switch, separating myth from maintenance fact with technical precision.

The Role of the Brake Pressure Switch in Freightliner Heavy-Duty Systems

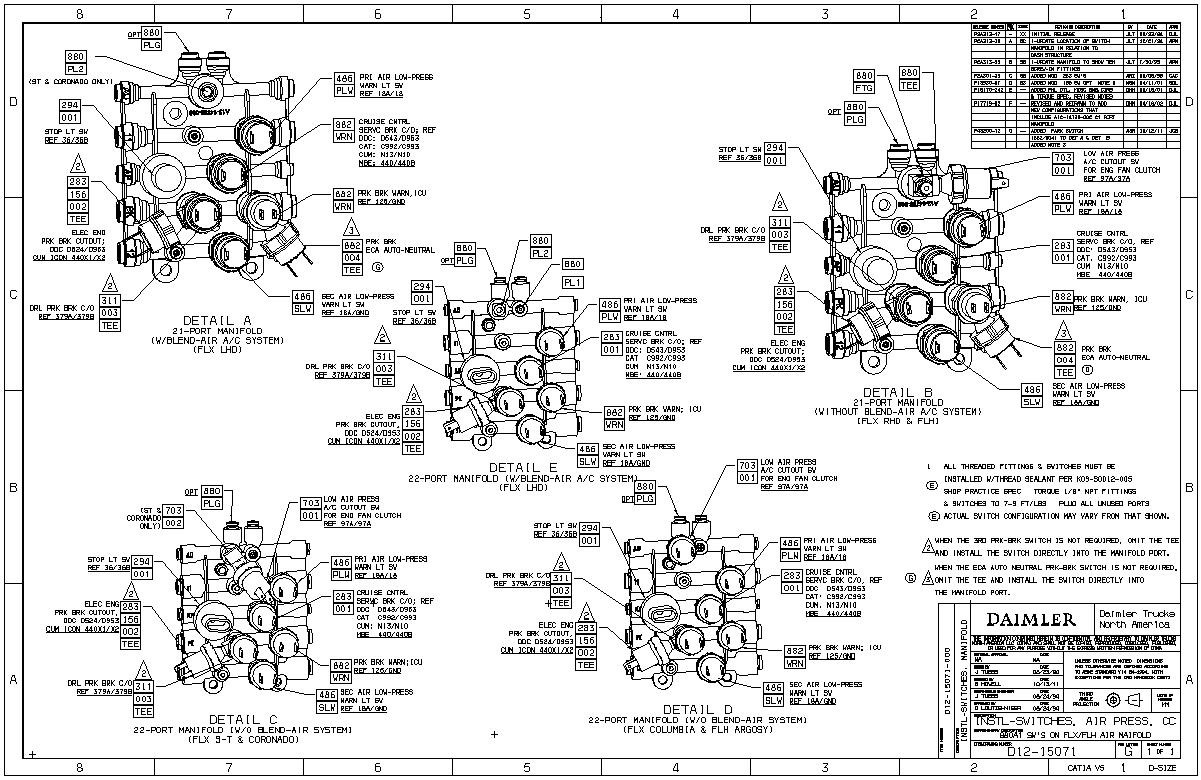

The brake pressure switch in Freightliner models functions as a sentinel for hydraulic brake integrity, continuously monitoring pressure within the master cylinder and brake lines.Installed near the master cylinder reservoir, it compares real-time pressure against calibrated thresholds—typically within 10–15% of recommended operating levels. When pressure falls below safe limits, signaling reduced brake fluid or system blockages, the switch activates a dashboard warning light and may trigger automatic pressure building (if equipped) to maintain partial braking function. This early alert allows drivers and fleet managers to respond before catastrophic failure occurs.

Unlike basic mechanical gauges, modern electronic versions integrate with onboard diagnostics (OBD-II), logging fault codes and enabling deeper analysis via diagnostic troubleshooting tools. As industry standards tighten, precise knowledge of this switch’s behavior becomes essential for compliant fleet safety management.

Common Symptoms of a Faulty Brake Pressure Switch

Recognizing the early signs of brake pressure switch failure is crucial for effective maintenance.Fleets and drivers often notice: - Persistent dashboard brake warning light, even after normal braking. - Reduced or inconsistent braking performance under load. - Spongy brake pedal feel, indicating lost hydraulic pressure.

- Inconsistent pressure readings on scan tools, despite no visible leaks. - Frequent activation of automatic pressure building (in systems with this feature). These symptoms rarely emerge in isolation; they signal underlying issues such as fluid contamination, internal switch defects, or wiring faults.

Technicians emphasize that ignoring these cues risks escalating failures—without timely attention, internal hydraulic components may suffer accelerated wear, leading to master cylinder seepage or completely locked brakes.

Core Diagnostic Techniques for Pressure Switch Failure

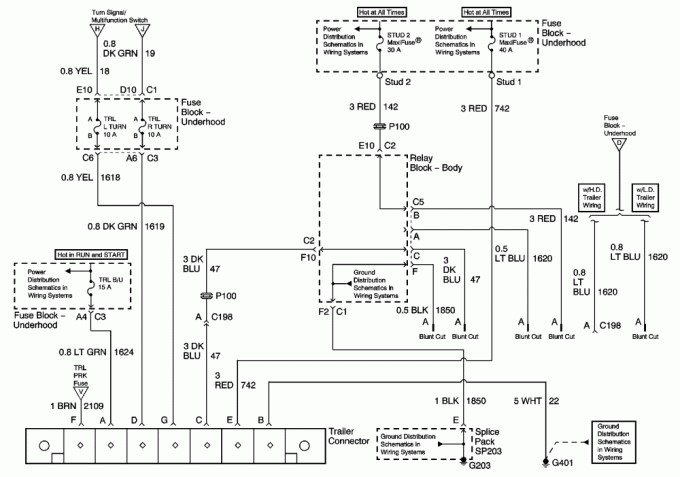

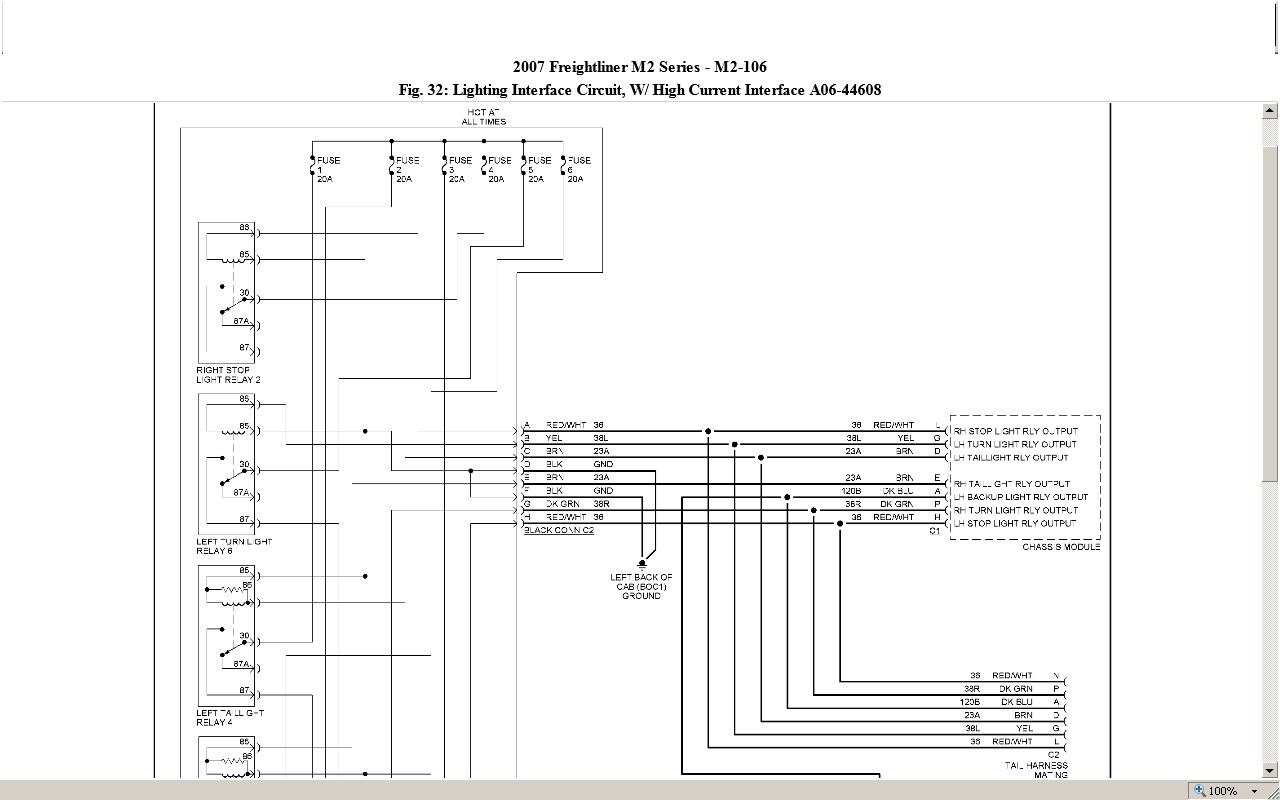

Diagnosing a brake pressure switch begins with confirmed warning indicators. Fleet managers should first verify the presence of dashboard illumination using diagnostic scanners, as visual cues alone are unreliable.Key diagnostic steps include: - **Visual Inspection:** Check plumbing for leaks or corrosion near the master cylinder. Fluid contamination—dirty or burnt-smelling hydraulic oil—often points to internal wear within the switch. - **Wiring Verification:** Inspect connectors for corrosion, loose grounds, or damaged insulation.

A damaged circuit can mimic switch failure, even when the component itself is functional. - **Pressure Testing:** Using specialized load testers, measure hydraulic pressure at the master cylinder outlet under brake application. Discrepancies between expected (typically 800–1,200 psi in Freightliner plays) and actual readings reveal switch inaccuracy or system failure.

- **Scan Tool Analysis:** Modern OBD-II systems capture live data streams and fault codes such as P0700 series or switch-specific DTCs. Interpretation of codes like “C0425 (Brake Pressure Switch Circuit Open)” guides repair focus toward specific failure modes. > “Many pay-for-safety fleets miss subtle leaks or early switch drift because they rely solely on the warning light,” notes Comfort Drive Maintenance Director Lisa Tran.

“A proper diagnostic blend of visual, electrical, and pressure verification roots out root causes accurately.”

Step-by-Step Repair: Isolating and Fixing the Switch

When a faulty pressure switch compromises system integrity, repair follows a structured sequence to ensure safety and longevity. **Step 1: Secure the Vehicle & Verify System Isolation** Turn off the engine and apply handbrake; depressurize brake lines by releasing pressure through the bleeder valve or pressure-release port. Waist belts and fall prevention gear are essential when handling high-pressure lines.**Step 2: Remove and Reset the Switch (if electrical)** Disconnect the switch harness connector—carefully pull connectors without yanking wires. Remove mounting bolts (often hidden under plastic covers), gently pull the switch, and inspect the seat for wear or debris. Reset may involve vacuum testing or using a reset tool specific to the model.

Reinstall with supplier-standard torque specs to prevent over-tightening or loosening. **Step 3: Replace the Pressure Switch (if faulty)** If pressure tests confirm dead switches—even after reset—fully replace the unit. Use OEM-specified wiring diagrams to align connectors correctly.

Torque bolts evenly to avoid stress fractures in plastic housing. Test newly installed units under controlled pressure with a calibrated gauge, verifying actuation at 850 psi minimum per Freightliner specs. **Step 4: System Flush & Fluid Management** Flush reservoir and lines using manufacturer-recommended hydraulic fluid (ISO VG 32 or equivalent), clearing debris and moisture.

Never reuse contaminated fluid—this prevents corrosion and maintains pressure fidelity. **Step 5: Advanced Diagnostics & Calibration** Recheck wiring continuity and ground integrity. Use scan tools to confirm signal consistency with the brake control module.

If pressure fluctuations persist, consider hybrid faults—some systems integrate ABS or EBD modules that complicate diagnosis. Fleet technicians report best practices include documenting part numbers, scan codes, and test results in service logs. “Traceability saves time and reduces retesting,” says over 15-year Freightliner mech Joe Malone.

“A documented repair path ensures consistency across shifts.”

Preventive Maintenance: Keeping the Brake Pressure System Robust

Proactive care extends switch lifespan and minimizes surprise failures. Key strategies: - Perform monthly visual checks for leaks, fluid discoloration, and connector cleanliness. - Schedule pressure tests every 6 months, especially after heavy hauling or road anomalies.- Train drivers to report subtle braking changes immediately—early reporting catches issues before they escalate. - Maintain clean fluid reservoirs using breather filters and sealed systems to prevent moisture ingress. “Preventive care isn’t expensive—it’s an investment in reliability,” emphasizes fleet safety consultant Mark Reynolds.

“Consistent attention to the pressure switch loop turns a reactive repair into a managed system health proactive habit.”

When to Replace vs. Repair: A Technician’s Decision Matrix

Not every fault warrants complete switch replacement. When pressure tests show mechanical behavior within ±5% tolerance and wiring checks pass, conservative repair—cleaning, recalibration, or component tuck-in—suffices.However, repeated reset failures, electronically logged endurance limits breached, or physical damage to internal diaphragms typically demand replacement. Using quality OEM parts ensures compatibility with Freightliner’s hydraulic thresholds and electronic signaling. When move to repair, precision matters—using tools like micrometer-equipped torque wrenches and pressure timers avoids over-tightening or misalignment, prolonging system integrity.

Operators using advanced diagnostic systems now leverage cloud-connected modules to share fault data across fleets, enabling predictive maintenance models that spot early switch degradation trends before failure occurs.

Common Pitfalls in Brake Pressure Switch Diagnosis

Even seasoned technicians fall into traps. Too often, switches are replaced unnecessarily based solely on dash illumination—just because the light is on doesn’t mean the switch is dead.Fluid contamination often masquerades as switch failure; cross-checking with a fresh sample prevents costly replacement. Wiring oversights are another hazard—forcing connectors during reset or skipping ground checks introduce intermittent faults. Technicians stress: “Diagnosis is 80% detective work.

Trust multiple data points before assuming replacement.” Moreover, ignoring pressure values above or below spec not only risks safety but voids potential warranties. Factory service bulletins confirm that updated calibration standards require revalidating switches post-repair against revised thresholds.

The Broader Impact: Safety, Efficiency, and Operational Trust

Mastering brake pressure switch diagnosis and repair is not merely a technical skill—it’s a cornerstone of freight safety culture.For Freightliner fleets, where load integrity and driver trust underpin daily operations, maintaining precise hydraulic feedback ensures responsive, predictable braking even in extreme conditions. The pressure switch acts as both guardian and messenger, turning silent system faults into actionable insights. With disciplined diagnostics, methodical repair, and proactive fluid and electrical care, fleets sustain operational excellence, reduce breakdown frequency, and uphold the safety legacy Freightliner’s reputation demands.

This system, small yet vital, proves that in heavy transport, reliability begins beneath the hood—one calibrated switch at a time.

Related Post

Happy 2025: A Blueprint for Transformation, Wellness, and Global Optimism

Unblocked Game 66: The Gateway to High-Scoring Chessbase Simulation Unblocked

Revolutionize Workday Celebrations with the HappyBirthdayMemeForCoworker: A Lighthearted Nudge for Team Spirit

Spurs Trade: Redefining Value in Global Commerce Through Strategic Innovation