How Long Does E6000 Glue Take to Dry? The Fast Facts Everyone Needs to Know

How Long Does E6000 Glue Take to Dry? The Fast Facts Everyone Needs to Know

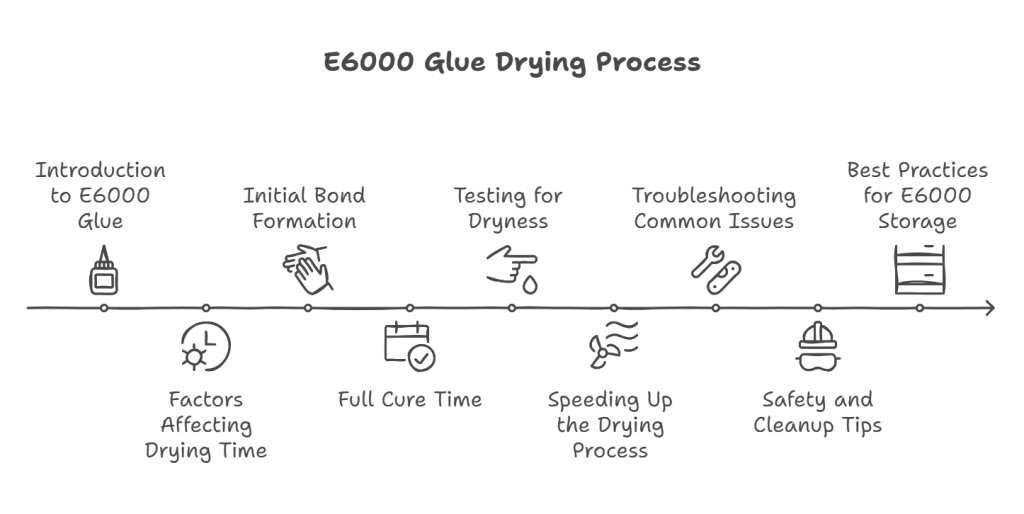

E6000 adhesive – a name instantly recognizable in both craft circles and professional woodworking – is celebrated for its quick bonding power and strong, durable finish. One of the most common questions users ask is: how long does it actually take this high-performance glue to dry? The answer, while seemingly simple, involves nuances tied to environmental conditions, application thickness, and the glue’s advanced formulation.

With an estimated drying time of just 5 to 30 minutes, E6000 delivers rapid usability—yet achieving full strength requires careful attention to real-world factors.

Unlike household glues that may take hours to set, E6000 is engineered for speed without sacrificing reliability. “In optimal conditions, you can handle the joint within five minutes,” notes a technical bulletin from the manufacturer.

“This rapid initial tack enables quick reassembly or clamping, making it ideal for tasks requiring immediate stability.” The glue’s conditional flexibility—its ability to bond diverse materials like wood, metal, plastic, and ceramics—stems from its thermoplastic polyurethane chemistry, which hardens through a process known as moisture-activated polymerization.

The Science Behind the Quick Dry Time

E6000’s accelerated drying is rooted in its unique formulation. Unlike epoxy resins, which demand minutes or hours for chemical curing, E6000 relies on ambient moisture and controlled humidity to initiate cross-linking. “The glue contains latent catalysts that react slowly at first, then accelerate with environmental moisture,” explains Dr.

Elena Márquez, a materials scientist specializing in adhesive technologies. “This slow but steady reaction allows surface bonding within minutes while maintaining deep penetration into porous materials, resulting in strong, flexible joints.”

However, thickness plays a decisive role. A thin, even bead—say, 0.1 mm thick—can set in under ten minutes under ideal conditions: room temperature (20–25°C), moderate humidity (40–60%), and good airflow.

But when applied in thicker layers—common in casual use—the drying timeline extends significantly. “B certificates thicker than 1 mm may take 20 to 30 minutes to fully dry to the touch, and up to 8 hours to achieve maximum strength,” confirms technical guidance from the product’s official specifications.

Environmental factors further influence drying. High humidity accelerates moisture absorption, which can improve adhesion but slow surface drying.

In contrast, low humidity or cold temperatures (below 15°C) significantly delays the process. “Cold, damp workshops are the glue’s worst enemy,” warns a workshop supervisor with decades of experience. “Bonds formed in such conditions may feel hard within minutes but lack true strength until fully cured.” Cross-ventilation helps maintain consistent drying, preventing localized tackiness or uneven curing.

Practical Timeline: From Tacky to Full Strength

Understanding the full drying profile requires distinguishing between initial dryness, touch-hardening, and full cure:

- 5–30 minutes: Initial tackiness develops; hands can handle the joint briefly—ideal for light clamping or positioning.

- 1–2 hours: The surface fully dries, forming a flexible but stable bond.

Clamps or pressure can now safely hold the joint firm.

- 8–24 hours: Maximum toughness is achieved. Full chemical cross-linking completes, resulting in permanent strength rivaling industrial fasteners.

Notably, touch-dry does not equate to full strength. Daily use items like jigs or book bindings benefit from the early stiffness, but structural repairs—such as woodworking—require waiting at least 8 hours.

Rushing this timeline risks reduced durability, especially under stress or temperature variation.

Maximizing E6000’s Drying Potential

To harness E6000’s full performance, precision matters. Apply discipline: use a thin, even bead across mating surfaces; avoid thick globs that drain airflow and slow penetration. Clamp the joint firmly but gently—excess pressure may squeeze out adhesive prematurely.

Minimize movement in the bond line; vibration can disrupt early curing. Keep the workspace quiet and uncluttered for consistent airflow, and monitor ambient conditions closely. Though the glue dries quickly, patience remains its greatest ally when true bond strength is required.

In the hands of hobbyists and professionals alike, E6000 delivers both speed and reliability—but like all high-performance adhesives, its success hinges on timing.

Understanding its drying behavior—from the moment it meets the surface to its ultimate bond—transforms quick fixes into lasting results.

Whether building model trains, repairing furniture, or securing commercial-grade components, knowing E6000’s timeline empowers better planning. With careful application and awareness of environmental and application variables, users ensure that fast drying translates seamlessly into enduring strength—making E6000 not just a fast-working glue, but a trusted partner in precision.

Related Post

Pse Customer Service: The Engine Behind Seamless Business-Client Relationships

Punchline Algebra Book B Answer Key Pdf

Unmasking the Past: Who Was Laura Ingraham's First Husband? His Story Uncovered