Where Are iPhones Made? A Deep Dive into Global Manufacturing and Supply Chains

Where Are iPhones Made? A Deep Dive into Global Manufacturing and Supply Chains

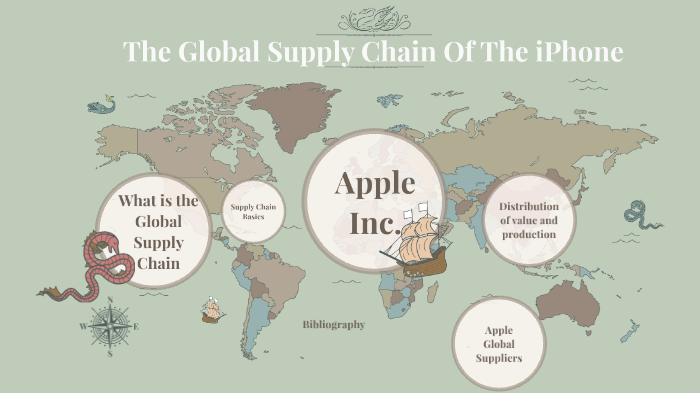

From sleek glass screens to precision-engineered components, iPhones represent a masterclass in global supply chain complexity—assembled not in a single factory, but across multiple continents. The production of Apple’s flagship devices reflects a meticulously coordinated network of manufacturing hubs spanning East Asia, Southeast Asia, and beyond, where specialized firms contribute to different stages of production. This global footprint enables Apple to combine cutting-edge innovation with cost-efficient, high-volume manufacturing.

Yet, far from being a secretive operation, iPhone production is a case study in transparency, division of labor, and strategic geographic placement.

At the heart of iPhone assembly lies a dominant manufacturing center in China—often described as the world’s electronics production capital. Over 90% of iPhones are assembled in China, where Apple’s core manufacturing partner, Foxconn (Hon Hai Precision Industry), operates massive facilities in regions like Shenzhen and Chengdu.

These plants employ hundreds of thousands of workers and run 24/7 cycles to meet global demand. "The speed and scale of production in Chinese facilities are unmatched," notes a former supply chain analyst from Apple’s internal reporting. "Each iPhone undergoes rigorous quality control before shipping—tested for functionality, aesthetic details, and durability."

East Asia: The Foundation of iPhone Hardware

Beyond China, Taiwan plays an irreplaceable role in the iPhone’s supply chain, particularly in the production of advanced semiconductor components critical to performance.Taiwan Semiconductor Manufacturing Company (TSMC) dominates the fabrication of Apple’s custom A-series chips—silicon engines more powerful than those found in most competing smartphones. These chips are not manufactured domestically in China or Apple’s own facilities, but in TSMC’s state-of-the-art foundries, predominantly located in Hsinchu and earlier in Macau before shifts in policy and geopolitics. Apple’s reliance on TSMC underscores a strategic dependency: the company’s ability to maintain performance leadership hinges on access to Taiwan’s cutting-edge fabrication capabilities.

Questions about production stability have arisen due to geopolitical tensions and natural disaster risks—issues highlighted during the 2011 Tohoku earthquake, which disrupted iPhone production across Asia. As a result, Apple has diversified manufacturing locations to reduce exposure.

Southeast Asia: Expanding the Production Network

To mitigate risk and respond to rising labor costs in China, Apple has significantly invested in assembly operations across Southeast Asia—particularly Vietnam, India, and Malaysia.Vietnam, in particular, has emerged as a key secondary hub, with companies like Foxconn and Wistron establishing large-scale facilities near Hanoi and Ho Chi Minh City. These plants now produce a substantial portion of iPhones, especially models targeting growing markets in Southeast Asia and Europe. In 2023, Apple reported that over 15% of global iPhone output originated from Vietnamese factories, a figure that reflects a deliberate diversification strategy.

India’s role is evolving rapidly as well. With government incentives, domestic component assembly initiatives, and growing demand, Chinese-made iPhones are increasingly supplemented by Indian-assembled units. Foxconn’s facility in Karnataka now assembles iPhones using local components and imported modules, signaling India’s deepening integration into Apple’s manufacturing ecosystem.

"Shifting assembly to Vietnam and India isn’t just about cost—it’s about resilience," observed a senior industry consultant. "Diversification reduces vulnerability to regional disruptions and aligns with Apple’s long-term operational agility."

Component Sourcing: A Global Web of Specialized Manufacturers

While final assembly concentrates in Asia, the true complexity lies upstream—in raw materials, semiconductor fabrication, and component production. IPhones depend on tens of thousands of parts sourced globally, from rare earth metals mined in Australia and Madagascar, to display panels from South Korean giants like Samsung Display and LG Display, and camera sensors developed with Japanese firms such as Sony and Canon.Even battery cells often combine materials from China, Japan, and South Korea. Apple’s supply chain transparency has grown markedly, publishing detailed lists of suppliers and production sites through its annual Supplier Responsibility Reports. This openness allows stakeholders—from investors to consumers—to trace the origins of iPhone components, reinforcing trust in performance and ethical sourcing.

Technological Sovereignty Meets Manufacturing Realities

Despite the global spread of production, a critical threshold remains: Apple’s custom silicon, designed and optimized by its own in-house team, is manufactured exclusively outside China. This compartmentalization reflects not only technological strategy but geopolitical caution. U.S.export controls and tensions with China have accelerated Apple’s push to secure alternative fabrication partners in Taiwan, Japan, and even the United States, where chip design is led internally but production remains abroad. Yet, even as executive control over design remains centralized in Cupertino, day-to-day manufacturing responsibilities are delegated to partners with deep regional expertise. The result is a hybrid model: Apple retains complete control over product vision and software integration, while leveraging a global network of trusted manufacturers.

Labor Practices and the Human Side of Production

Behind the efficiency and scale lies a workforce of millions—many employed in factories under strict Apple labor standards. The company enforces rigorous audits, mandates fair wages, prohibits forced labor, and requires safe working environments. While challenges persist—particularly around overtime and working conditions—the factory systems have improved significantly over the past decade.Reports from independent observers note that modern facilities now feature enhanced ventilation, ergonomic workstations, and digital monitoring to protect worker well-being. Apple’s “Supplier Status Report” affirms ongoing efforts to scale ethical practices, acknowledging past shortcomings while highlighting investments in training programs and sustainability initiatives across its supply chain.

The Impact of Geopolitical and Economic Shifts

The iPhone’s production map continues to evolve amid shifting global dynamics.Rising labor costs in China, trade policy shifts, and the global push for supply chain resilience have accelerated Apple’s diversification across Southeast Asia and India. Additionally, U.S. Inflation Reduction Act incentives and the CHIPS Act have encouraged localized component production, though full reshoring remains impractical for complex electronics like iPhones.

nevertheless, China’s entrenched ecosystem—its skilled workforce, integrated logistics, and supplier density—ensures it remains indispensable. As one industry analyst noted, “You can move assembly elsewhere, but no place matches China’s convergence of capabilities, speed, and scale—at least for now.”

The Road Ahead: A Balanced Ecosystem of Innovation and Manufacturing Where are iPhones made? Not in one place, but across a meticulously orchestrated network spanning continents.

From Taiwan’s silicon foundries to Vietnamese assembly lines and Indian component integration, Apple’s supply chain blends precision, resilience, and speed. As technology advances and global risks mount, the company’s model balances control and flexibility—leveraging global specialization while safeguarding core competencies. The iPhone’s journey from design to dish is a testament to modern industrial globalization: complex, strategic, and indispensable to maintaining Apple’s leadership in a fiercely competitive market.

Related Post

Funniest Trump Quotes That Still Snort with Ancient Humor

Understanding Latto’s Parents: The Family Foundation Behind the Rise of a Rising Star

Exploring The Gypsy Rose Mums Crime Scene Pictures: A Deep Dive

Who Is Tyana Hansen the Australian Playboy Model