Thermodynamic vs Kinetic Product: The Invisible Battle Shaping Chemical Futures

Thermodynamic vs Kinetic Product: The Invisible Battle Shaping Chemical Futures

In the silent arena of molecular transformations, two distinct pathways govern how chemicals evolve: thermodynamic and kinetic products. Understanding this fundamental dichotomy reveals why certain reactions yield stable, long-lasting compounds while others trigger rapid but fleeting changes. The choice between thermodynamic and kinetic outcomes is not merely academic—it defines material stability, reaction efficiency, and even industrial process design.

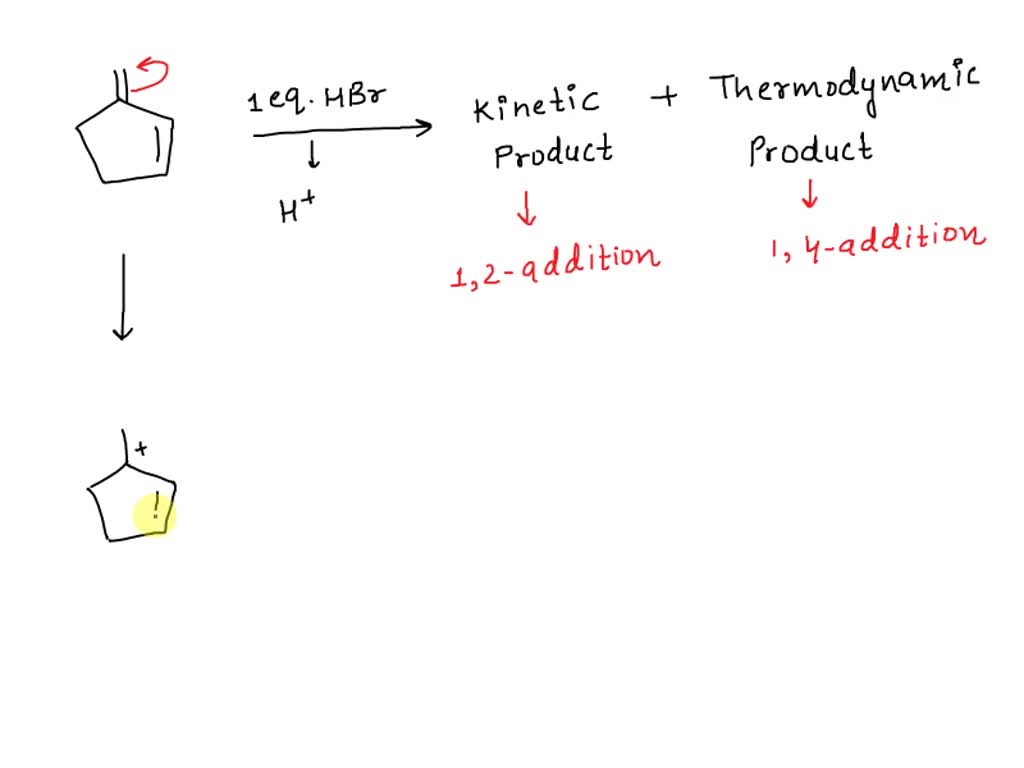

At the heart of this distinction lies energy and time. Thermodynamic products represent the most energetically favorable state, stabilized through prolonged equilibration and minimal activation barriers. Kinetic products, conversely, form quickly under short timescales—often trapped in metastable configurations that lack ultimate stability but dominate initial reaction dynamics.

This contrast shapes everything from polymer durability to catalytic efficiency and pharmaceutical shelf life.

Thermodynamic Products: The Long Game of Molecular Stability

Thermodynamic products emerge over extended reaction periods when systems reach equilibrium. They embody the lowest free energy state dictated by thermodynamics, stabilized by extensive atomic rearrangement and minimized activation barriers. Because these states optimize energy efficiency, they directly determine the final composition of stable materials.Defining thermodynamic products requires consideration of: - **Gibbs free energy (ΔG):** A negative ΔG confirms spontaneity and stability at equilibrium.

- **Equilibrium constraints:** Extended reaction times and thermal stabilization allow molecules to rearrange and achieve original'État stable form. - **Long-term durability:** Thermodynamic products resist change, making them ideal for applications requiring longevity. For example, in the formation of structural polymers like polyethylene, prolonged heating often drives the system toward thermodynamic stability.

Under optimal conditions, these materials maintain integrity for decades, outperforming faster-forming alternatives that result in kinetically trapped networks prone to degradation.

Key characteristics of thermodynamic products: - High stability at equilibrium - Minimal residual stress and chemical reactivity - Reliance on gradual energy dissipation - Typically non-spontaneous on short timescales

This stability becomes critical in materials science, where design goals demand resilience against environmental stressors—UV radiation, thermal cycling, and mechanical strain—all of which act against metastable, kinetically favored species. Engineers prioritize thermodynamic pathways to ensure materials endure not just initial performance, but enduring functionality.

Kinetic Products: The Speed-Driven Shortcut of Reaction Dynamics

In contrast, kinetic products form rapidly during the early stages of a reaction, often bypassing full energy optimization.They arise when reaction rates outpace equilibrium, capturing molecules in metastable states that are too energetically costly to overcome within practical timeframes. Though unstable in the long run, kinetic products often dominate transient reaction landscapes due to their formation speed.

Critical features of kinetic products include: - Rapid formation under short activation time - High local energy barriers that prevent conversion to thermodynamic minima - Sensitivity to initial conditions and environmental triggers such as temperature spikes or catalyst presence - Common in reactions requiring immediate product generation, like polymerization initiators or explosive combustion intermediates A classic illustration occurs in the birch reduction reaction, where electron transfer precursors generate kinetic products that rapidly snowball over thermodynamic stability. Without containment, these species decompose or revert, underscoring their inherent transience.

Core traits of kinetic products: - Formation occurs rapidly under mild activation conditions - Characterized by high initial reactivity - Vulnerable to thermal or catalytic shifts toward equilibrium - Common in transient, high-reactivity environments

While kinetic products excel in early-stage reactivity—enabling efficient catalysis or controlled flash reactions—relying solely on them jeopardizes material longevity and functional predictability. Their rapid generation often sacrifices structural robustness, turning fleeting advantages into vulnerabilities under prolonged stress.

Industrial and Scientific Implications: When Speed Meets Stability

The contrast between thermodynamic and kinetic outcomes influences fields ranging from pharmaceuticals to energy storage. Consider catalytic converters: optimized catalysts favor thermodynamic product formation to ensure complete pollutant conversion over time.Meanwhile, polymer curing processes balance kinetically driven initial sets with thermodynamic crosslinking to achieve durable, heat-resistant materials. Chemical engineers and materials scientists routinely manipulate reaction parameters—temperature, pressure, catalyst selection—to direct systems toward desired pathways. Thermal techniques encourage system equilibration, while fast-response conditions lock in kinetic products for immediate functionality.

"This choice defines performance, safety, and sustainability." remarks Dr. Elena Torres, a chemical engineer specializing in reaction dynamics. "Thermodynamic stability ensures reliability; kinetic speed fuels innovation.

Engineers must align reaction design with the intended lifecycle of the product.” Applications underscore this balance: - **Battery materials:** Lithium-ion cathodes rely on thermodynamic stability for cycle life, while kinetic factors govern charge/discharge rates. - **Pharmaceuticals:** Metastable polymorphs deliver enhanced solubility and bioavailability, but thermodynamic predominance ensures shelf stability. - **Catalysts:** High-temperature processes favor kinetics for rapid turnover; stable, thermodynamically favored catalysts prevent deactivation.

The interplay shapes modern chemistry’s success: from lab-scale synthesis to large-scale manufacturing. Ignoring either facet risks failure—material degradation, inconsistent yields, or unintended reactivity that compromises safety and function.

Real-world trade-offs illustrate the critical balance: - Catalytic converters: Use thermodynamic tuning for permanence but require kinetic ignition efficiency - Polymer science: Kinetic initiation enables fast manufacturing; thermodynamic crosslinking guarantees durability - Drug design: Metastable forms enhance delivery, yet must resist premature decomposition via kinetic traps

Ultimately, thermodynamic and kinetic products represent complementary extremes—each vital in its own domain. Understanding their mechanisms empowers chemists and engineers to predict outcomes, refine processes, and innovate with precision.

The ability to steer reactions between speed and stability is not just a technical skill; it’s a cornerstone of progress in materials, energy, and medicine.

In the end, the distinction between thermodynamic and kinetic products is far more than theoretical. It is the silent choreographer behind every enduring material and fleeting reaction, shaping what lasts and what vanishes. This foundational contrast reveals the silent logic governing chemistry’s most consequential transformations—forever balancing vulnerability and resilience.

Related Post

What Is Exactly the West in Terms of Internationalty? A Deep Dive into Its Global Role and Legacy

Exploring Alternatives to Gorecenter: The Ultimate Guide to Trustworthy, Efficient, and Secure Platforms

Republican or Not gameshow sketch on SNL pokes fun at GOP fury over Liz Cheney

Analyzing the Enduring Inheritance of The Companion From The Animated Series