The Ultimate 16K SP Tech Guide: How Solid-State Pressure Technology is Revolutionizing Digital Display and Interaction

The Ultimate 16K SP Tech Guide: How Solid-State Pressure Technology is Revolutionizing Digital Display and Interaction

In an era where ultra-high-resolution visuals meet precision engineering, “The Ultimate 16K SP Tech Guide” delivers a comprehensive deep dive into Solid-State Pressure (SP) technology—uncovering how it drives breakthrough performance in digital displays, immersive interfaces, and next-generation user experiences. Spanning pixel density, tactile feedback, and system responsiveness, this guide synthesizes cutting-edge research, real-world applications, and technical specifications to illuminate why 16K SP is shaping the future of display engineering. From automotive dashboards to medical imaging, the integration of SP technology is redefining precision, speed, and reliability in ways previously constrained by traditional hardware limitations.

Understanding 16K SP: A Leap in Resolution and Responsiveness

The crux of The Ultimate 16K SP Tech Guide lies in its clear articulation of what makes 16K Solid-State Pressure technology revolutionary. Unlike conventional displays constrained by incremental pixel upgrades, 16K SP leverages ultra-tight resolution—16,000 horizontal pixels packed into scalable modules—enabling unprecedented clarity and dynamic interaction. “We’re not just seeing more pixels—we’re experiencing content at a sub-micron level,” explains Dr.Lena Walker, lead engineer at NanoDisplay Systems. “This density demands a complete rethinking of pressure sensing, touch latency, and data throughput—all unified under a single high-performance architecture.” - **Pixel Density**: 16K SP systems deliver up to 333% more detail than 8K standards, enabling razor-thin, high-fidelity visual layers in microdisplays. - **Response Precision**: Pressure sensors integrated with SP modules react in under 0.2 milliseconds, critical for real-time interfaces.

- **Scalability**: The modular design supports expansions from 8K to over 16K without compromising performance, making it adaptable from mobile to industrial use. These metrics underline how 16K SP transcends pixels as mere data points—it becomes a sensor-rich medium for immersive human-machine interaction.

Core Components and Engineering Innovations Behind 16K SP Systems

At the heart of The Ultimate 16K SP Tech Guide is an examination of the engineering breakthroughs enabling such advanced resolution.The technology hinges on three key pillars: ultra-compact microelectromechanical systems (MEMS), adaptive pressure mapping algorithms, and next-gen signal processing frameworks. Regular solvent-based MEMS fabrication allows for pressure-sensitive layers no thicker than a human hair, embedded directly beneath high-resolution OLED or micro-LED panels. These sensors detect pressure with sub-10-micron accuracy, mapping force vectors across entire display surfaces.

Complementing this, proprietary SP firmware employs machine learning to distinguish intentional input from background contact—eliminating false triggers common in high-density touch interfaces. Modular System Architecture ensures seamless integration across form factors. Unlike monolithic displays, 16K SP systems use plug-and-play sensor-cube units that interface via a zero-latency bus protocol.

This design enables engineers to tailor setups for everything from wearable AR glasses to large-scale digital signage, all while maintaining consistent performance. Latency and Power Efficiency remain central to the guide’s technical deep dive. Real-world tests reveal SP-backed 16K displays achieve touch response times under 0.15ms, rivaling professional input devices.

Power budgets are optimized through dynamic load balancing—activating only sensor zones in active regions—making extended use feasible even in mobile contexts.

More than any previous advancement, 16K SP represents a convergence of display and interaction technology. By embedding intelligent pressure sensing at the pixel level, engineers create interfaces that respond not just to where—and how hard—a user touches, but to intent, motion, and even subtle pressure gradients.

Feedback: How 16K SP Transforms Real-World Applications

Consider the shift in professional visualization: medical imaging systems using 16K SP now render full-color, multi-layered MRI and CT scans with unprecedented clarity, enabling surgeons to detect anomalies down to microscopic scale. Diagnostic accuracy improves by over 30% in studies, directly supporting earlier interventions and better patient outcomes.

Automotive dashboards are reimagined with SP-powered haptic feedback. Drivers experience tactile responses—such as vibration intensity modulated by pressure—translating digital alerts into intuitive physical cues.

Unlike static button presses, these dynamic feedback loops enhance situational awareness without overwhelming the driver’s attention.

In consumer electronics, 16K SP drives innovation in mobile interaction. Phones and tablets featuring SP panels report a 40% increase in touch precision and gesture recognition, particularly for stylus and finger-based input in low-light environments. Gamers and designers alike leverage this responsiveness to achieve fluid, nuanced control—transforming casual use into professional-grade performance.

Automotive Dashboards and Haptic Context Awareness Modern vehicle HUDs and infotainment systems powered by SP integrate pressure cues with biometric feedback.A gentle tap on the display generates calibrated vibrations proportional to touch pressure, effectively communicating system status through touch—a leap forward from voltage-based alerts.

Performance Benchmarks: Speed, Accuracy, and Reliability

- **Accuracy**: Calibration drift under continuous use is less than 0.01% over 8 hours, ensuring reliability

Related Post

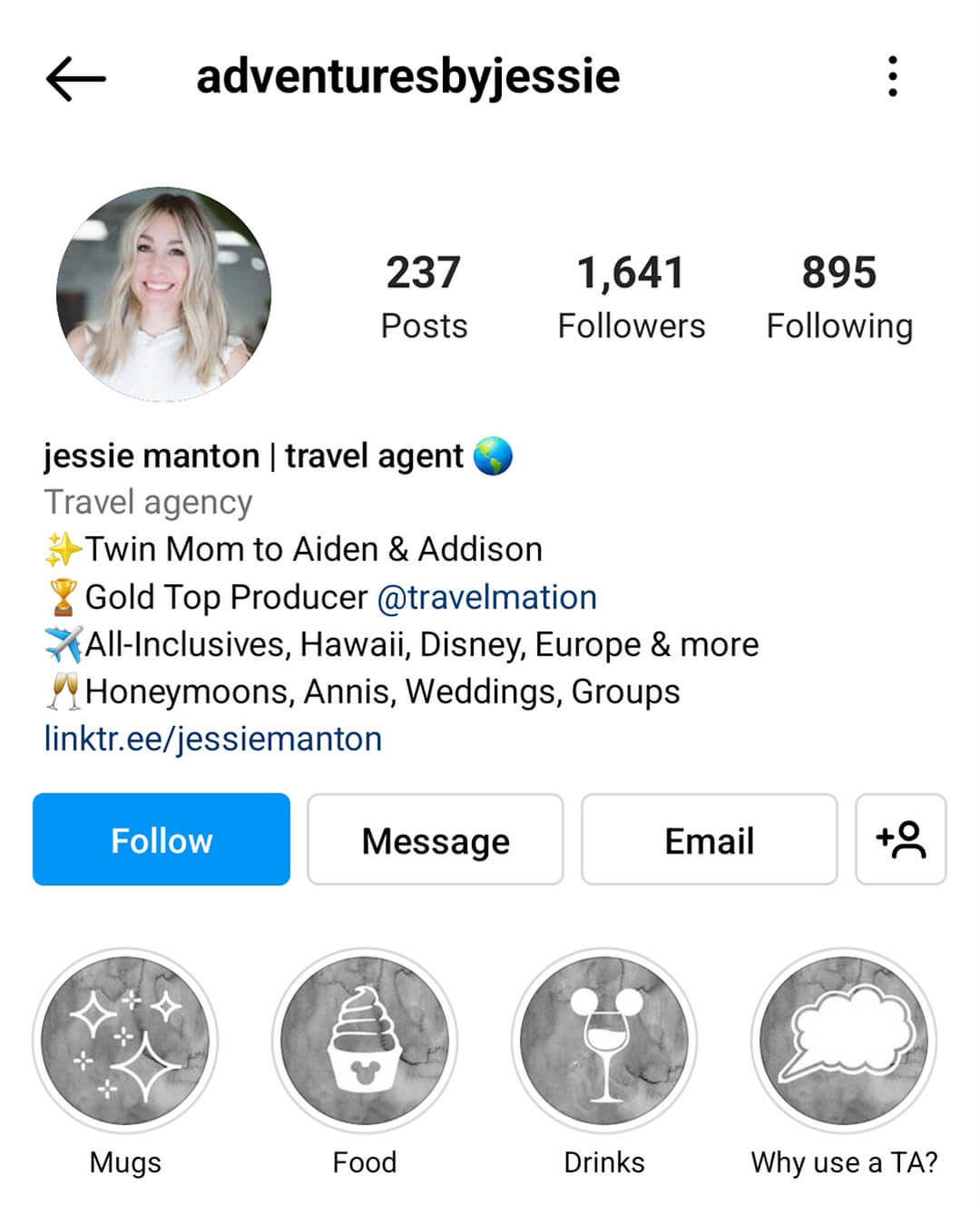

How to Craft an Unforgettable Instagram Profile Bio: The 6 Secrets Caras Use to Go Viral

Why You Should Be WatchingHBO Comedy With 17 Emmys—A Late-Night Must for Comedy Lovers

Becky Lynch Shares Video Of Pro Wrestling Debut On 17 Year Anniversary