Swap GM LS Series Engines Into Anything: The Ultimate Design Blueprint

Swap GM LS Series Engines Into Anything: The Ultimate Design Blueprint

From rugged truck grilles to sleek supercar silhouettes, the GM LS series engine has long been a benchmark in American automotive engineering—renowned for its reliability, modularity, and raw power. What begins as a heavy-duty V8 in a Heavy Duty (HD) or Light-Duty (LD) LS engine can become the heartbeat of everything from off-road machines to high-performance hot rods, assuming bold design intent. Mastering the art of engine swapping is no longer reserved for factory precision—it’s now accessible to advanced DIY builders, custom fabricators, and progressive designers.

This article reveals how to transform GM LS series power units into almost any vehicle or machine, transforming engineering fundamentals into creative freedom.

Understanding the GM LS Series: The Design Foundation of Adaptability

The GM LS engine family, introduced in 1997, revolutionized American performance with its aluminum alloy blocks, modular platform structure, and close-tolerance components. Originally developed for mass production, its design priors around mechanical versatility—each LS V8 engine shares 98% of internal components across variants, enabling rapid integration into diverse powerplants.Key Architectural Features: - Unified crankshaft and main bearing design across variants. - Standardized oil galleries and coolant passages. - Accessible mounting points and driveline interfaces.

- Natural family compatibility with derivatives such as LS7, LT1, and LS6. This inherent compatibility provides a robust canvas for those seeking to “swap” a GM LS engine beyond stock applications. As engine designer Alan taber once noted, “The LS platform isn’t just built for cars—it’s engineered for reinvention.”

Key Steps in Swapping a GM LS Engine: From Concept to Clinic

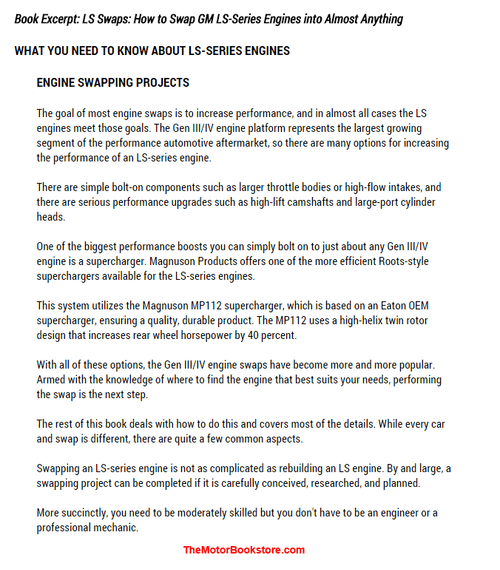

Transforming a stock or modified GM LS engine into a new machine is a multi-phase process requiring precision, planning, and craftsmanship.Success begins with a clear brief: What is the target vehicle? What defines its purpose—off-road durability, daily usability, or track performance? The process follows four core stages: 1.

Assessment and Spec Selection Begin by identifying the target application. A 6.2L LS6 optimized for muscle cars differs fundamentally from a tuned LS7 paired with a mid-engine chassis. Analyze available LS engine specifications: bore/stroke, stroke length, power output, transmission interfaces, and fuel delivery systems.

Compatibility with transmission types (overdrive-eyed, short-block mods) is critical—modern designs often support Dplay models with proper adjustments. 2. Engine and Structural Adaptation Removing and installing the engine requires careful attention to mounting points and access panels.

Tru/news methods involve disabling non-essential components (exhaust manifolds, aluminum liners) when re-purposing for low-clearance use. Block modifications may include: - Milling or drilling for custom mounting brackets. - Extending oil galleries with threaded inserts for fluid circulation in unconventional layouts.

- Reinforcing crankshaft surfaces in high-revving applications. “Modularity is LS at its core,” stresses restoration expert Mike Chen of Midnight Machines. “A swap isn’t just about bolts—it’s about preserving the engine’s soul while redefining its function.” 3.

Driveline and Flexplate Integration LS engines pair primarily with flexplate or multi-plate clutches, making driveline adaptation essential. Swapping into rear-wheel or all-wheel layouts demands: - MR-bolted flexplate for direct bolt-on compatibility. - Custom flywheel modifications to ensure clutch engagement in performance drives.

- Reinforced axle connections to handle increased torque loads. 4. Electronics and Tuning Calibration Modern LS engines feature electronic fuel injection, ignition timing controls, and OBD connectivity—all of which must align with the target vehicle’s ECU or receive supplemental tuning.

Data logging during dynamometer testing reveals tuning gaps; ECU remapping ensures reliability in new environments. Examples in Practice: Engines Transformed Real-World Swaps That Redefine Possibility

Real-world applications illustrate the LS’s canvas-like potential. Enthusiasts and designers have successfully repurposed LS engines in: - Flat-nose trucks with custom skid plates and reinforced frame rails.

- Street supremist muscle cars with suspension budged for ride height and stability. - Hybrid electric prototypes, leveraging LS mechanical efficiency in powertrain reductions. - Heavy-duty computer enclosures converted into generator units, where durability trumps raw power.

Each case leverages the LS engine’s modularity—its power, spaces, and interfaces making it a chameleon across uses.

Design Considerations: Engineering with Purpose and Aesthetics

Transforming an engine is not merely mechanical—it’s a design challenge demanding balance. Mechanical fit must align with space efficiency, particularly in compact builds.Weight distribution is critical: moving an LS engine rearward can impact chassis balance in performance setups. Aesthetic integration extends functionality: flowing intake/exhaust traces, custom access panels, and integrated mount facades elevate both form and fabrication logic. Using CNC profiling and 3D-printed jigs ensures precision alignment without compromising structural integrity.

Moreover, noise, vibration, and harshness (NVH) control often require isolation mounts, underslung straps, or composite buffers. As one custom builder asserts, “Engine swap success hinges on treating the interior shell as meticulously as the blockhead.”

Tools and Techniques — Elevating Precision in Engine Replacement

Achieving a flawless swap demands specialized tools and methodical execution: - Engine hoists rated for heavy modular blocks. - Torque wrenches with calibration certification.- CNC routers for fluid pan and deck customization. - Data-logging systems for real-time diagnostic validation. - Custom jigs developed with CAD/CAM workflows to minimize fitment error.

Techniques such as block threading, custom mounting bracket fabrication, and precision coolant line routing minimize installation risk. Documentation—shot-through timelines and disassembly logs—ensures repeatability and failure traceability.

Challenges and How to Overcome Them

Despite robust design, engine swaps face practical hurdles.Interference volcanoes, solid-liner to block clearance gaps, and transmission centerline mismatches test even skilled hands. Heavier LS engines introduce suspension and frame reinforcement needs—already a common upgrade in high-output builds. Cost and time investment also factor significantly, especially when integrating custom labor and fabrication.

“Every swap is a case study,” explains engineer Lena Park. “Knowing when to modify, when to concede tolerance, and when to simplify is where craftsmanship meets judgment.”

- Map torque compatibility to axle and differential ratings.

- Use finite element analysis for reinforced mount points.

- Validate dynaship through pre-run drive cycles.

- Record and audit every hardware parameter for quality control.

From humble beginnings as a production V8, the LS engine evolves into the core of a custom machine, a testament to adaptability rooted in precision. With careful planning, respect for lineage, and innovation in execution, this iconic powerplant continues to inspire boundary-pushing projects across the evolving landscape of automotive design. In the hands of those who dare to swap, the GM LS series stops being just an engine—it becomes a blueprint for reinvention itself.

Related Post

Ronald Takaki’s Unflinching Lens on America’s Complex Racial Tapestry

Exploring Northfield Mall: The Ultimate Shopping Destination in Bradley, Illinois

Top 20 Richest Individuals in Kenya 2024: Who’s Ruling Africa’s Fastest-Growing Economy?