Submarine Building In Connecticut: A Legacy Of Innovation That DivenS Into History

Submarine Building In Connecticut: A Legacy Of Innovation That DivenS Into History

From quiet coastal towns to the heart of America’s cold-war naval strategy, Connecticut stands as a cornerstone of submarine construction—where engineering mastery met strategic necessity to forge vessels that redefined underwater warfare. For over a century, the state’s shipyards have been globally recognized not just for crafting submarines, but for pioneering technologies and innovations that advanced maritime defense and marine engineering. This deep-rooted tradition of submarine building reflects more than industrial output—it embodies a relentless commitment to precision, secrecy, and breakthrough design, shaping both national security and technological progress.

The establishment of key facilities along Long Island Sound—particularly in Groton—cemented the region’s strategic importance. Groton, a mere two hours from Hartford, became synonymous with submarine innovation. Here, the space allowed proximity to naval command centers and robust infrastructure, enabling rapid advancement from hull design to propulsion systems.

<

Connecticut builders refined hull shapes using early computational fluid dynamics, improving maneuverability and stealth. - **Propulsion Systems**: Transitioning from diesel-electric to nuclear propulsion revolutionized underwater endurance. Although nuclear submarines are rare in Connecticut, the state’s mechanical workshops led critical subsystems development—including pump-jet propulsors and modular reactor integration.

- **Stealth Technology**: Cutting-edge anechoic coatings, vibration suppression, and low-noise propulsion enabled quieter vessel operation. Connecticut-based engineers pushed boundary-pushing materials science to minimize acoustic signatures, making modern U.S. attack and prisoner submarines nearly undetectable.

Universities and engineering schools in Connecticut partnered with industry leaders to advance computational design tools and sensor integration. These alliances ensured submarine builders remained at the vanguard of both combat capability and materials science. “Our engineers don’t just build submarines—they design the future of undersea dominance,” said a retired chief naval architect from Electric Boat, quoting from an exclusive interview.

“Every weld, every circuit, every system is optimized not just for performance, but for adaptability. Connecticut’s shipyards teach you to think decades ahead.”

- **Tomahawk Launcher Integration**: Long-range cruise missile systems demand precision-guided navigation, seamlessly linked to submarine stabilization and steering—a capability refined in Connecticut facilities. - **Tomcat and Ghost Systems**: Submarines equipped with cutting-edge sonar arrays and satellite-linked data networks owe much to Connecticut’s expertise in fused sensor technology and communications’. - **Autonomy And Artificial Intelligence**: Emerging developments in AI-assisted navigation and threat detection, tested and deployed in part through Connecticut-based R&D, are redefining how submarines operate independently underwater.

Laborers often cite pride in contributing to a lineage where every rivet and computer algorithm serves national defense with unyielding responsibility. Therefore, the story of submarine construction in Connecticut is not merely industrial history—it’s a narrative of continuous innovation, strategic foresight, and human ingenuity woven into the fabric of America’s undersea dominance.

From Wartime Foundations to Cold War Prowess

During World War II, massive mobilization transformed idle drydocks into productive centers, churning out Gato- and Balao-class logistics and attack submarines under intense secrecy. These early efforts laid the groundwork for post-war technological ascent. 548 missions by Connecticut-built submarines symbolize this era of commitment.

Among the most iconic: the USS *Gato* (SS-211), named after a World War II-era submarine, and later, advanced *Los Angeles*-class attack subs, designed for long-duration patrols and intelligence gathering. Each hull represents incremental innovation, driven by necessity and excellence. << Strategic Location and Infrastructure Advantage Connecticut’s

Related Post

Jimmy Neutron’s Black Girl: A Bold Leap in Animation’s Representation Frontier

David Adedeji Adeleke Jr.: The Rising Star Redefining Afrobeats

March 5th Zodiac: What Your Zodiac Sign Reveals for Hard Work, Creativity, and Connection

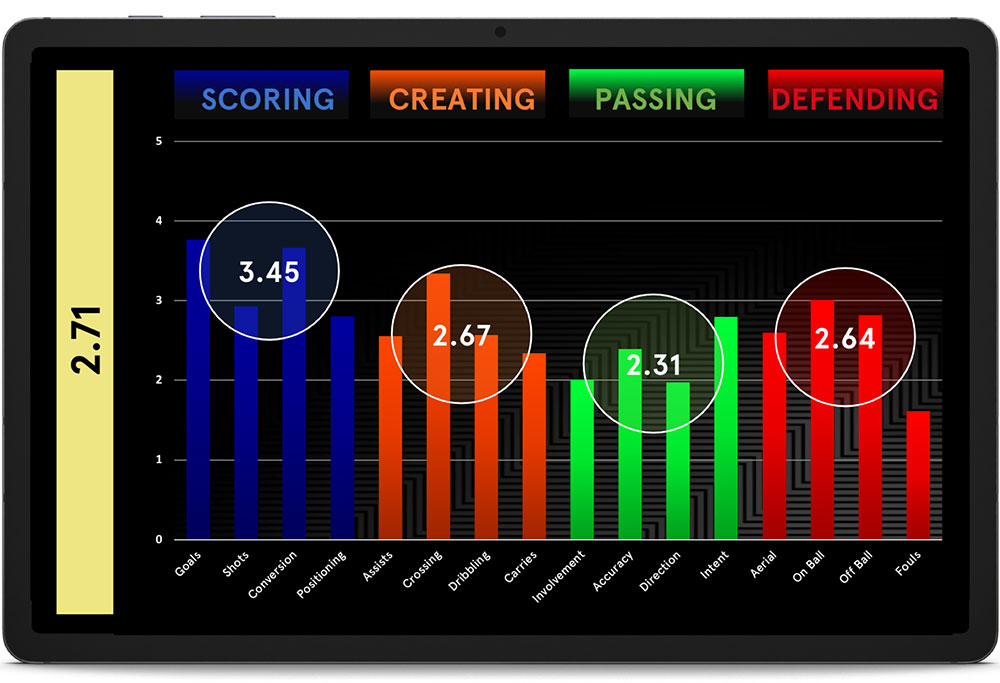

Fox Sports Net Unveils Game-Changer: How Legendary Player Insights Are Redefining Modern Sports Analysis