Ship3d Revolutionizes Maritime Design: The Future of Ship Modeling is Here

Ship3d Revolutionizes Maritime Design: The Future of Ship Modeling is Here

Ship3d stands at the forefront of 3D modeling innovation, transforming how naval architects, designers, and maritime engineers conceptualize and construct vessels. By combining intuitive software interfaces with powerful rendering capabilities, Ship3d enables the creation of highly accurate digital twins of ships—accelerating design cycles, reducing costs, and enhancing precision across the entire lifecycle of marine vessels. From concept sketches to full-scale simulations, Ship3d empowers teams to visualize, test, and refine ship designs with unprecedented speed and fidelity.

Redefining Digital Prototyping with Ship3d

Ship3d leverages advanced parametrica modeling and real-time visualization to shift the paradigm from physical mockups to virtual engineering.Unlike traditional CAD tools, which often sacrifice speed for complexity, Ship3d merges ease of use with professional-grade accuracy, allowing designers to generate detailed hull forms, superstructures, and internal layouts in minutes. “Ship3d’s strength lies in its balance—bridging creativity and engineering rigor,” notes marine systems engineer Dr. Elena Rodriguez.

“I’ve seen prototype iterations shrink from weeks to hours, all while maintaining compliance with international maritime standards.” This transformation starts with intuitive 3D sculpting tools that map water dynamics automatically, ensuring hull shapes optimize hydrodynamics without manual recalculations. Engineers can simultaneously simulate stress points under various loads, enabling proactive corrections before physical construction begins. Ship3d also integrates seamlessly with FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) software, transforming digital models into validated performance tools.

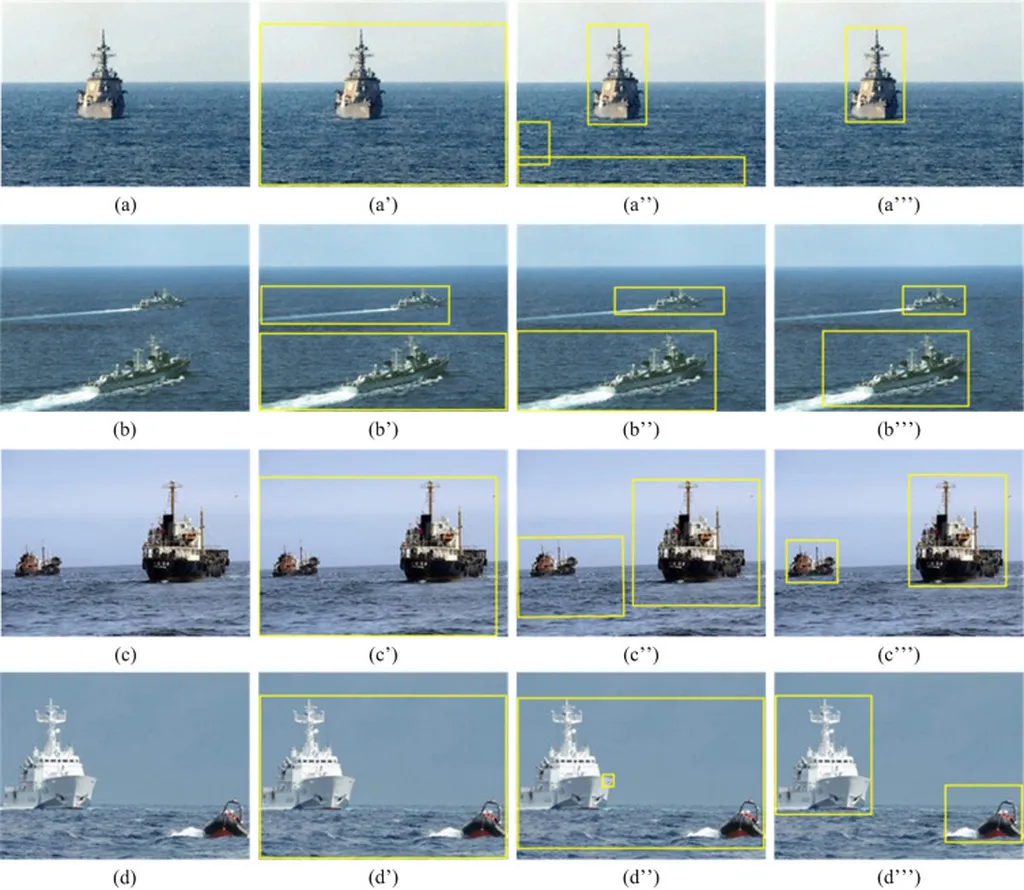

Precision Modeling: From Hull to Deck

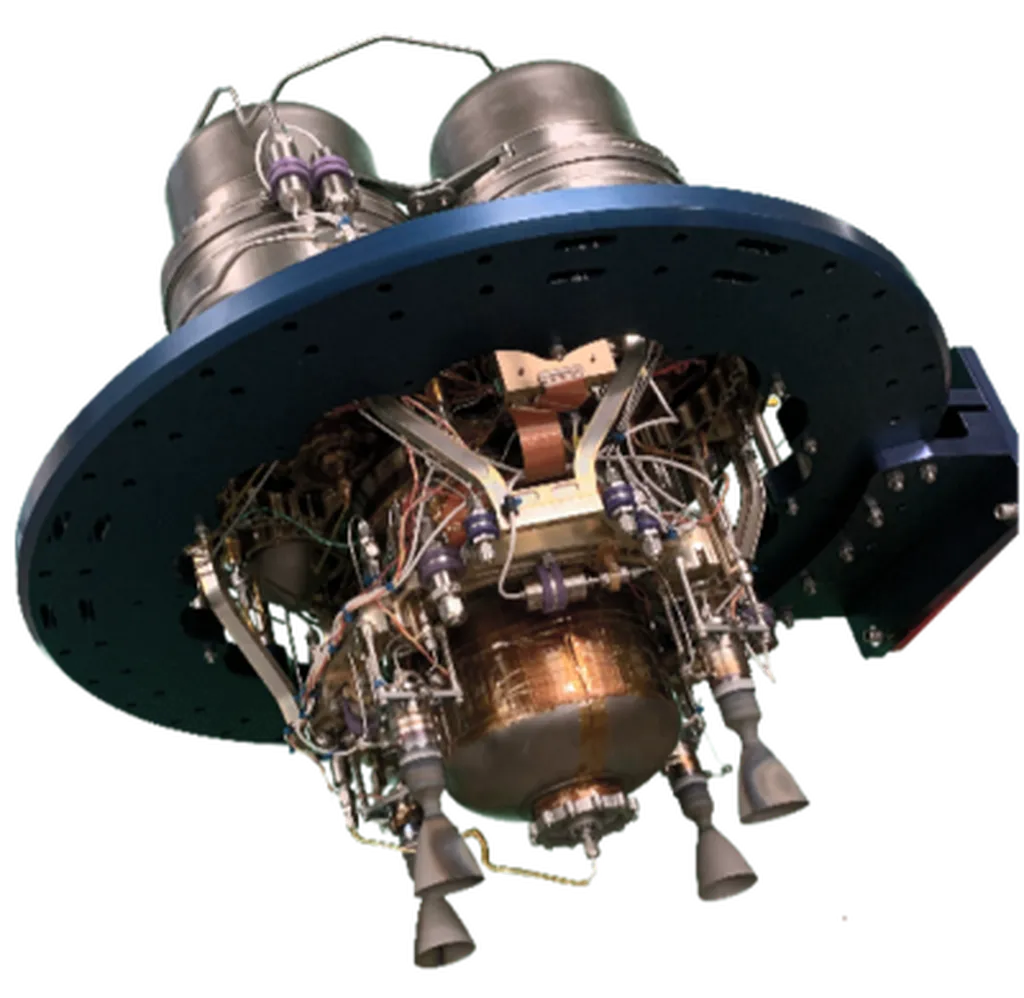

At the core of Ship3d’s strength is its ability to deliver microscopic detail across every component. The platform supports full-scale digital twins that replicate not only geometry but also material properties, paint finishes, and equipment placement. For deck layouts, designers manipulate modular elements—booms, railings, vehicle ramps—with real-time collision avoidance, ensuring safe, functional access at every scale.Nautical lighting systems, mechanical configurations, and even interior cabin environments can be rendered with photorealistic textures, bringing conceptual designs to vivid life. Navigation systems, propulsion units, and avionics interfaces are modeled with layered data, enabling engineers to inspect wiring harnesses and control pathways as if in the engine room. “Ship3d eliminates guesswork,” says senior maritime designer James Cho.

“With embedded measurement and annotation tools, our team checks alignment and spacing down to the millimeter—before a single bolt is tightened.”

Streamlining Collaboration and Project Management

One of Ship3d’s most impactful features is its cloud-based collaboration engine, designed for distributed teams across fathoms apart. Projects hosted on the Ship3d platform support synchronized editing, version control, and real-time feedback loops. Stakeholders—marine architects, naval engineers, client representatives—access secure, up-to-date models from any browser, reducing email chains and fragmented data silos.The integration with BIM and PLM workflows further enhances lifecycle management. Ship3d models export natively to industry standards (STEP, IGES, DXF), enabling smooth transfer to fabrication yards and maintenance teams. Project timelines are managed through embedded scheduling tools, with alerts for design milestones and regulatory compliance checkpoints.

This end-to-end integration cuts rework and ensures alignment from concept to commissioning.

Real-World Applications and Industry Adoption

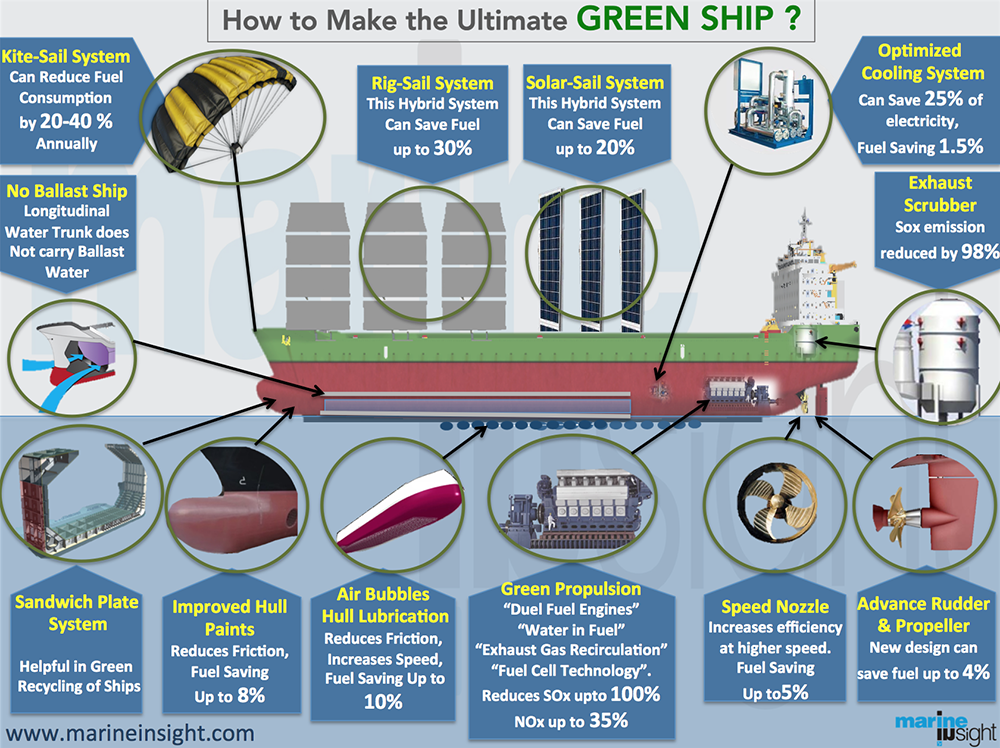

Across naval shipyards, commercial ferry operators, and offshore energy firms, Ship3d is proving its versatility. In commercial maritime, luxury container vessels and cruise ships use Ship3d to simulate passenger flows and optimize energy efficiency, directly impacting operational savings.Offshore contractors deploy Ship3d to model wind farm support vessels, enabling risk assessment under extreme sea conditions prior to vessel build-up. Even defense sectors leverage Ship3d for stealth hull designs and unmanned surface vessel (USV) prototypes, where iterative modeling directly affects mission success. “Ship3d isn’t just software—it’s a strategic asset that speeds delivery and strengthens design confidence,” says maritime consultant Mark Thompson.

“We’ve deployed it on projects spanning 100-meter freighters to experimental research ships, and the consistency and speed of output remain unmatched.”

The Road Ahead: AI Integration and Beyond

As Ship3d evolves, artificial intelligence is becoming a key differentiator. Built-in generative design modules suggest optimized hull configurations based on performance criteria, learning from thousands of previous designs to reduce trial-and-error. Machine learning algorithms now assist in predicting corrosion patterns and structural fatigue, enabling predictive maintenance models embedded directly within the vessel’s digital twin.Cloud infrastructure upgrades support large-scale concurrent modeling, making distributed teams more effective than ever. With APIs enabling deeper connection to IoT sensors on actual ships, real-time data feeds can now validate and update Ship3d models during operation—closing the loop between design and deployment. Ship3d is not merely a modeling tool; it is the foundation of a smarter, faster, and more connected maritime industry.

By redefining digital prototyping at its core, it accelerates innovation, reduces risk, and ensures that tomorrow’s ships are built not just on paper—but in precision, performance, and possibility.

Related Post

Iran’s Democratic Past: A Struggle for Progress Before the Seismic 1979 Upheaval

Gigi Dolin Blasts Haters Who Body Shamed Her