Revolutionizing Apparel Aesthetics: The Comprehensive Clothing Decoration Workflow

Revolutionizing Apparel Aesthetics: The Comprehensive Clothing Decoration Workflow

In the ever-evolving world of fashion and retail, customization has shifted from luxury accessory to essential expectation—driving brands to adopt intricate, scalable decoration workflows that merge creativity with precision. At the core of this transformation lies the ProcessFlowDiagramClothingDecorationAWorkflow, a structured, multi-stage system that enables seamless integration of design, production, and quality control. This workflow, designed to streamline every step from digital mockup to final product, empowers designers and manufacturers to deliver personalized garments with speed, accuracy, and visual impact.

The ProcessFlowDiagramClothingDecorationAWorkflow functions as a visual and procedural blueprint, mapping how ideas transform into decorative apparel through sequential stages. It integrates software-driven design tools, material selection algorithms, and manufacturing coordination—all unified by standardized checkpoints. Each phase, meticulously defined, ensures consistency, minimizes errors, and supports rapid iteration based on client feedback or market trends.

Core Stages in the Clothing Decoration Workflow

The workflow begins with Concept Development, where designers leverage digital canvases to sketch motifs, patterns, and structural alterations.Uses such as Adobe Illustrator integrated into the system allow for scalable vector-based creativity, ensuring designs remain crisp at any size. This stage sets tone, style, and target audience, creating a shared digital brief baseline for the entire team.

Next, Design Refinement and 3D Visualization transforms flat concepts into lifelike previews. Using augmented reality (AR) and rendering engines, designers simulate how fabric textures, color palettes, and decorative elements interact under real-world lighting.“Accuracy in visualization prevents costly missteps,” says lead textile engineer Elena Marquez. “Clients can visualize変更 before a stitch is sewn—this is where confidence is built.” These 3D mockups serve as approval gateways before progressing to production. Joining the creative phase is Material and Tech Selection, a critical juncture where sustainability, durability, and cost intersect.

The workflow offers integrated databases of fabrics—ranging from organic cotton and recycled polyester to high-performance performance textiles—accompanied by technical specs like strengths, dye compatibility, and touch feel. Advanced filters let users match materials to seasonal collections or niche markets, such as athleisure requiring moisture-wicking fabric or formal wear demanding luxe blends.

Following selection, Pre-Production Preparation activates.

This phase converts approved digital designs into manufacturable blueprints. Artwork is processed into cutter-ready formats (e.g., DXF or Gerber), mock patterns are optimized for minimal waste, and cut lists are generated with recipe items down to individual thread counts per garment. Cutting mechanisms—whether automated laser cutters or human-operated die presses—are pre-tested to ensure alignment with tight tolerances, reducing fabric waste to under 5% in optimized runs.

With pre-production complete, the Mass Decorating and Application Phase unfolds.Here, automated dispensing systems apply sublimation inks, embroidery, laser-cut patterns, or hand-painted motifs with pixel-perfect accuracy. Dip-dye techniques, metallic foils, and patch finishing are executed under controlled humidity and temperature to preserve colorfastness. The system tracks every batch with unique QR codes, enabling traceability from thread spool to finished shirt.

Final Quality Assurance remains non-negotiable. Automated optical inspection detects inconsistencies in print placement, color matching, or stitch density, while human inspectors validate nuanced details like seam integrity or fluorescence under UV light. Each garment receives an audit-ready certification, ensuring alignment with brand standards and customer expectations.

Emerging technologies further refine the workflow. AI-driven trend forecasting inputs seasonal motifs directly into the design phase, while blockchain integration enables full supply chain transparency—critical for eco-conscious brands. Cloud-based collaboration supports distributed teams, allowing real-time updates across designers, manufacturers, and retailers.

“The future isn’t just about decoration—it’s about intelligent, responsive decoration,” notes workflow architect Amir Malik. “Our system learns, adapts, and scales with market velocity.”

Related Post

British Nobleman Rankings: Decoding the Aristocracy’s Hierarchical Power in Modern Times

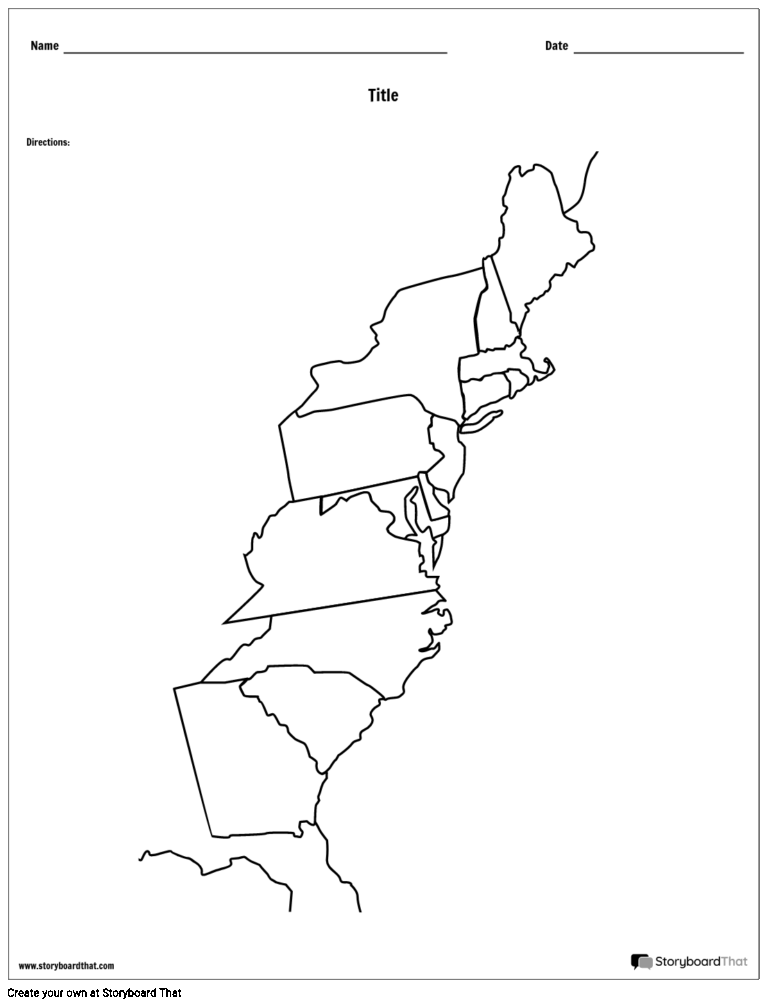

Uncover the 13 Colonies: A Detailed Printable Map Reveals the Colonial Snapshot That Shaped America