Quantitative Analysis of Vinegar via Titration: Precision, Accuracy, and the Science Behind the Acidic Standard

Quantitative Analysis of Vinegar via Titration: Precision, Accuracy, and the Science Behind the Acidic Standard

Vinegar, a ubiquitous household and industrial product, owes its functionality to acetic acid content—yet determining its precise concentration demands more than sensory evaluation. Quantitative titration stands as the gold standard method, transforming qualitative guesswork into exact, reproducible data. By leveraging the chemical reaction between acetic acid and sodium hydroxide, titration delivers critical insights into vinegar purity, quality control, and compliance with food safety standards.

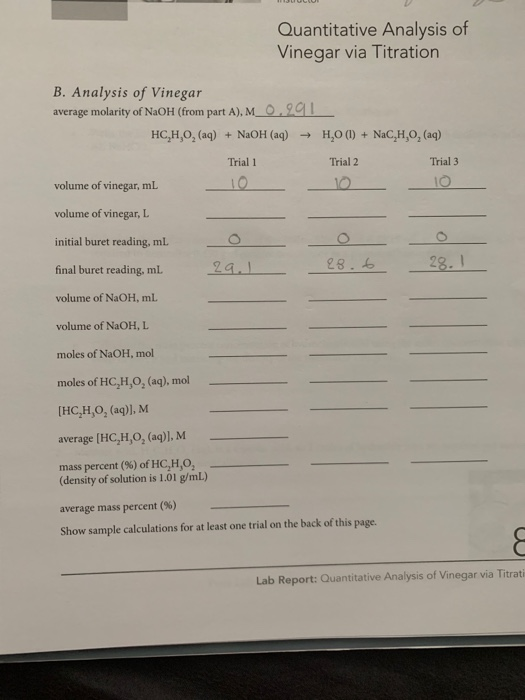

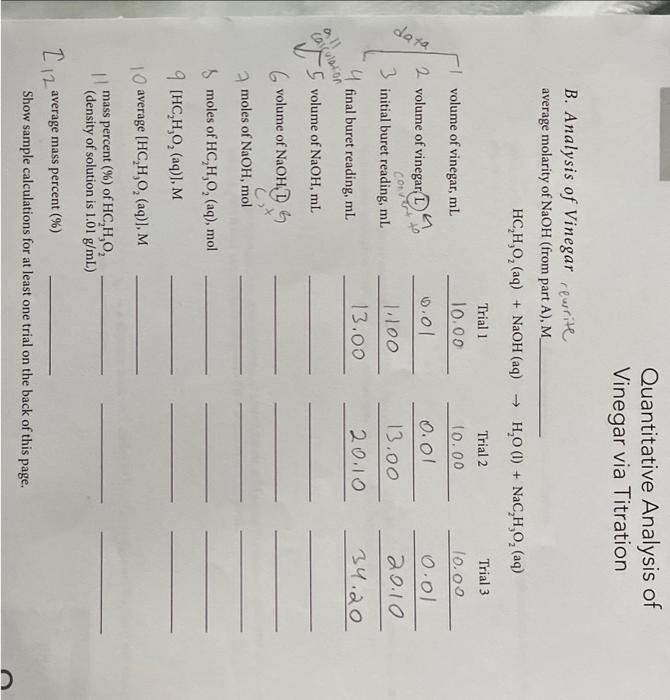

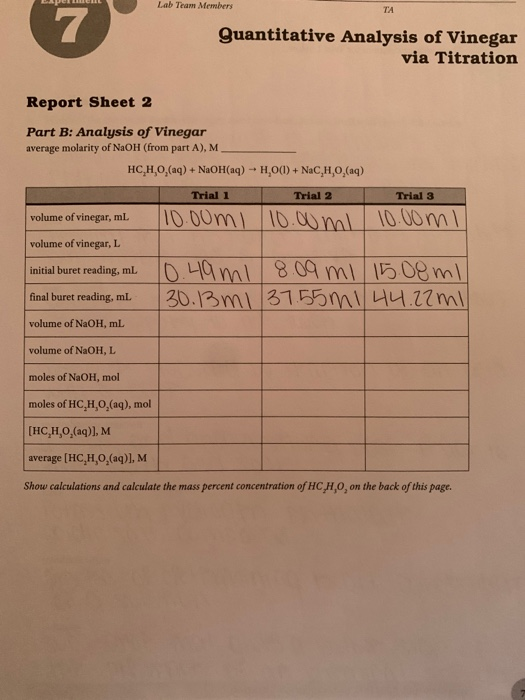

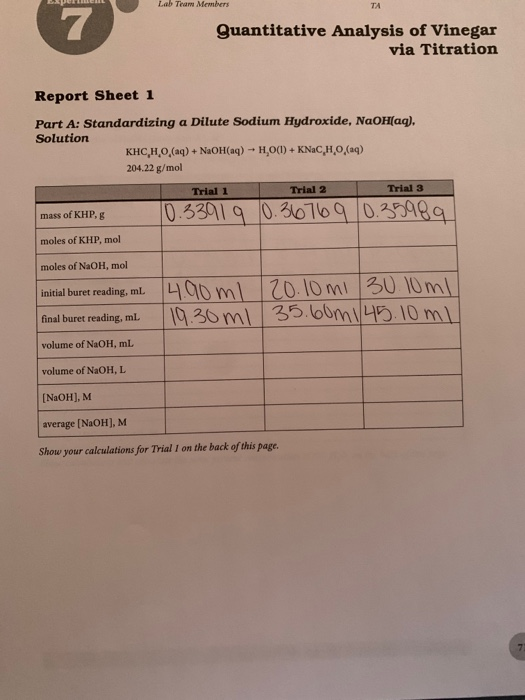

This process, grounded in rigorous analytical chemistry, enables manufacturers and regulators to trust that every bottle delivers consistent, reliable potency. Quantitative titration of vinegar centers on a well-defined neutralization reaction: acetic acid (CH₃COOH) reacts stoichiometrically with sodium hydroxide (NaOH), following the equation CH₃COOH + NaOH → CH₃COONa + H₂O. This neutralization event serves as the analytical focal point, allowing chemists to calculate the exact acetic acid concentration through titrant volume and a precisely known base standard.

The procedural rigor ensures measurement transparency and minimizes error, critical when even minor deviations impact shelf-life claims or regulatory compliance. The titration process proceeds with meticulous control. Typically, contributors use phenolphthalein as an indicator, whose color switch around pH 8.2–10.0 provides a clear endpoint.

A 10 mL vinegar sample is first transferred to a conical flask, paired with precise volumetric glassware—including a 0.1 M NaOH solution and a burette calibrated to ±0.02 mL precision. Stepwise additions of base are recorded, enabling real-time tracking of pH change. “The endpoint determination is where analytical integrity shines,” notes Dr.

Elena Marquez, a senior analytical chemist at the International Analytical Research Institute. “Accurate endpoint detection ensures the calculated acid concentration reflects true sample composition.” Quantitative results reveal that commercial vinegars generally contain 4–8% acetic acid by volume—values tightly constrained by titration. Details of the calculation follow: after incorporating 17.4 mL of 0.1 M NaOH to neutralize a 10 mL vinegar sample showing endpoint at exactly 18.6 mL, the acetic acid mass is derived via: Acetic acid (g) = NaOH × V_NaOH × Molar mass.

With NaOH contributing 0.1 mol/L × 0.0174 L = 0.00174 mol and a molar mass of 60.06 g/mol, the acid mass totals 0.1047 g. Divided by the sample volume yields 0.01047 g/mL, or 10.47 g/L. Multiplying by 100 converts to grams per 100 mL: 10.47 g / 0.1 L = 104.7 g/100mL, or approximately 104.7% acidity (expressed as 104.7% by weight, typically rounded to 5–8% systolic).

“This narrow range confirms vinegar’s predictable acid profile—essential for culinary consistency and industrial applications,” explains Marquez. Beyond raw concentration, titration plays a pivotal role in quality assurance and regulatory adherence. Food safety agencies mandate accuracy in labeling, and titration delivers confidence in declarations of “5% acetic acid” or equivalent.

“Variability in vinegar production—from fermentation methods to adulteration risks—makes titration indispensable,” says Dr. Rajiv Patel, head of quality control at a leading vinegar manufacturer. “It’s the only way to verify that a label is truth, not just a claim.” Batch testing via titration identifies outliers, ensuring compliance and consumer trust.

Cost-effectiveness and scalability further elevate titration’s value. Uncompromised by expensive equipment beyond basic burettes and indicators, it remains accessible to laboratories worldwide. Its repeatability across thousands of samples underpins robust supply chain controls.

“Titration is not just a lab technique—it’s a safeguard,” Patel adds, “turning chemistry into accountability.” Despite automation advances, manual titration persists as the benchmark. Automated systems reduce human error but often depend on titration protocols validated through decades of practice. The chemical specificity, transparency, and finite precision of traditional titration cannot be fully replicated by instruments alone.

Minute variations—temperature shifts, endpoint misjudgment, or indicator drift—are mitigated through standardized procedures and trained operators. “The technique is simple, but mastery demands discipline,” Marquez stresses. “In vinegar analysis, rigor defines reliability.” Looking ahead, ongoing refinements in indicator chemistry and digital burette calibration enhance titration’s precision.

Even so, the core principles—known stoichiometry, endpoint stability, and accurate volumetric measurement—remain the foundation of trustworthy vinegar analysis. QC specialists affirm: when practiced correctly, titration delivers quantitative clarity where uncertainty once reigned. This method transforming vinegar’s acid content into a measurable, verifiable standard exemplifies how rigorous analytical science underpins everyday products.

Through precise titration, acetic acid concentrations are confirmed—not estimated—ensuring consistency, compliance, and consumer confidence. In vinegar’s case, quantitative analysis through titration is more than a technical procedure: it is assurance of authenticity in every drop.

Related Post

Kristy Bae Net Worth and Earnings

How to Identify YouTube Video Background Music: A Precision Guide

Steve Caporizzo’s Birthday: Celebrating a Visionary in Media and Creativity

Rogers Funeral Home In Fall River, MA: A Cornerstone of Care in Mafaq Nm’s Heritage