Osc Vs Asc Malfunction: Unmasking the Truth Behind Hydraulic System Failures

Osc Vs Asc Malfunction: Unmasking the Truth Behind Hydraulic System Failures

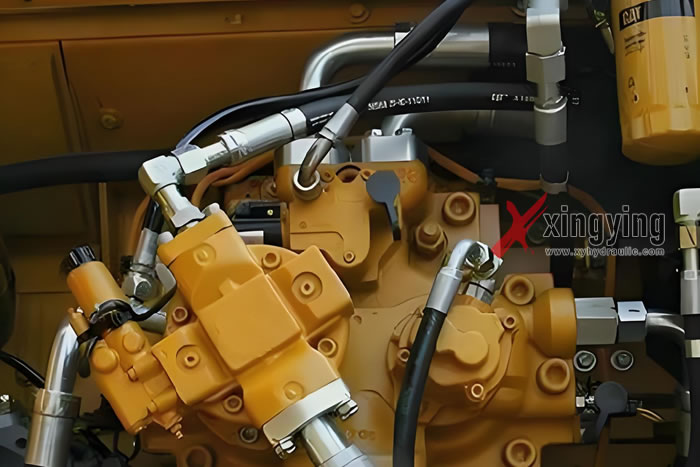

In the high-stakes world of industrial machinery and mobile equipment, reliable hydraulic operation is non-negotiable. Yet, when Osc versus Asc malfunction chains into failure, downtime, safety risks, and costly repairs ensue. This comprehensive guide dissects the root causes, symptoms, diagnostic methods, and preventive strategies behind Osc and Asc malfunctions—two pivotal components in hydraulic control systems.

Whether you’re an operators, maintainers, or engineers, understanding these failures empowers smarter troubleshooting, proactive maintenance, and system resilience.

Understanding the Roles of Osc and Asc in Hydraulic Systems

Osc and Asc are central to the metering and directional control of hydraulic fluid flow. Though often confused, they serve distinct functions: Osc modulates flow rate—actively mixing or diverting hydraulic fluid to control speed—while Asc directs flow in two opposing directions, typically enabling forward and reverse motion in mobile hydraulics (e.g., skid-steers, backhoes).Their synchronized operation ensures precise motion, but even minor deviations can trigger catastrophic system failures. Key contrasts: - Osc controls flow velocity through variable aperture adjustments, critical for speed regulation. - Asc governs flow direction, enabling bidirectional control of actuators.

- Both depend on accumulator integrity, valve integrity, and fluid cleanliness. - When either malfunctions, cascading errors propagate: pressure spikes, erratic actuator behavior, or complete system stalling.

Malfunctions rarely occur in isolation; they are usually the symptom of deeper root causes ranging from contamination to mechanical wear.

Common Causes of Osc Malfunction

Osc failure typically stems from mechanical, hydraulic, or environmental factors that impair flow modulation.Key contributors include: - **Valve Wear or Sticking:** Oscuators and delay valves degrade over time due to repetitive actuation, leading to sluggish response or jamming. - **Fluid Contamination:** Particulates or degraded fluid disrupt precision metering, causing erratic flow or pressure surges. - **Hydraulic Lock or Stagnation:** Blockages in fluid lines restrict movement, trapping internal components and freezing valve openness.

- **Electrical or Sensor Failure:** In electronically controlled Osc systems, sensor drift or faulty feedback disrupts timing algorithms. "Osc malfunctions are often subtle until they escalate—patterns like jerky motion or delayed response rarely appear in isolation," notes mechanical systems expert Dr. Elena Cho, “They’re the system through the cracks impedance before total failure.”

Recognizing early indicators—unusual valve sounds, fluctuating pressure gauge readings, or inconsistent actuator response—is critical to avoiding cascading failure.

Common Causes of Asc Malfunction

Asc system malfunctions primarily disrupt directional control, compromising mobility and safety.The most frequent culprits include:

Related Post

Sebastián Rulli Bio Wiki Age Height Angelique Boyer Tv Shows and Net Worth

Fox News Emily Uninates the Critical Debate on AI Regulation: When Innovation Meets Accountability