Mastering Geometric Dimensioning and Tolerance with the GD Benefits Portal: Unlocking Precision in T-Berial GD Data

Mastering Geometric Dimensioning and Tolerance with the GD Benefits Portal: Unlocking Precision in T-Berial GD Data

Navigating the complexities of Geometric Dimensioning and Tolerance (GD&T) within the GD Benefits Portal’s manage page represents a pivotal shift in how engineering teams maintain precision, consistency, and communication across product development. As aerospace and automotive manufacturing increasingly rely on stringent geometric controls, professionals demand clear, accessible tools to interpret and apply GD&T standards efficiently. The GD Benefits Portal’s dedicated manage page for T-Berial GD benefits streamlines this process—enabling engineers, quality inspectors, and design leads to access, verify, and manage GD&T implementations with enhanced clarity and control.

This article explores how the portal’s interface transforms theoretical GD&T principles into actionable data workflows, supported by real-world applications and best practices.

The Role of GD—Benefits Portalmanage Page in Modern GD&T Implementation

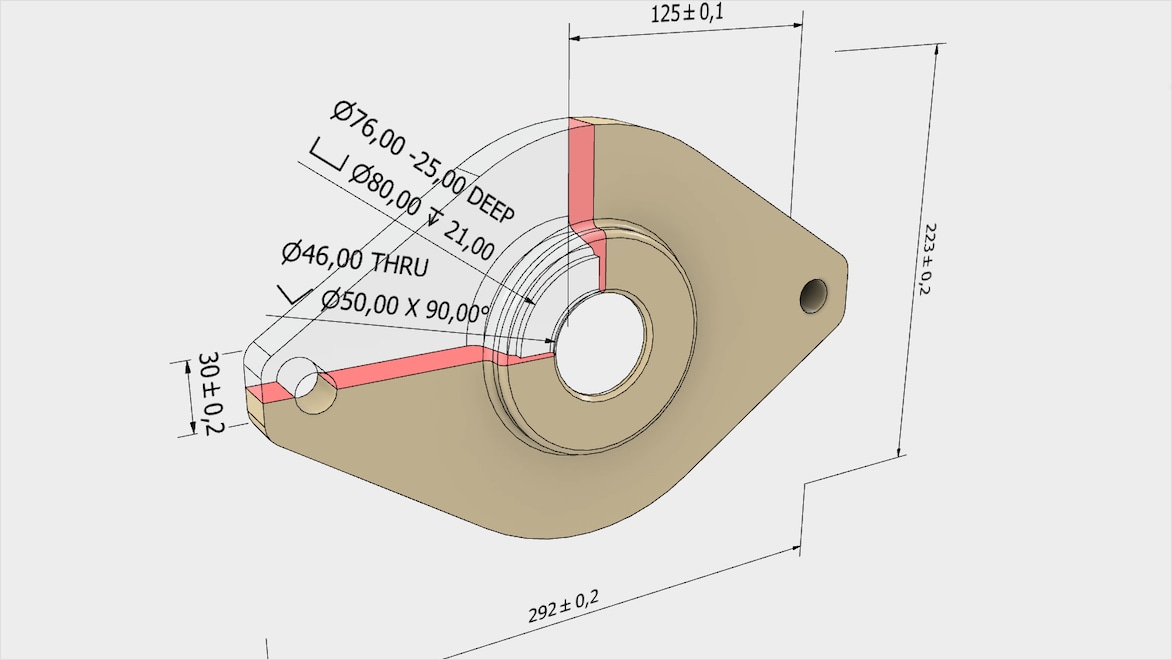

At its core, the benefits of integrating the GD Benefits Portalmanage Page lie in its ability to centralize and standardize geometric dimensioning and tolerance data. The portal acts as a digital hub where dimensional specifications are not only documented but also visually interpreted and linked to project workflows.For example, instead of manually tracing GD symbols across CAD models, users can consult the manage page to view dynamic 3D visualizations of dimensions, symmetry controls, and position relations—all annotated with tolerance values and ASME Y14.5 compliance notes. This reduces ambiguity and accelerates decision-making during design reviews. Internally, this functionality cuts rework by up to 30%, according to recent pilot deployments in industry-standard manufacturing plants.

Key Features of the T-Berial GD Benefits Portalmanage Page

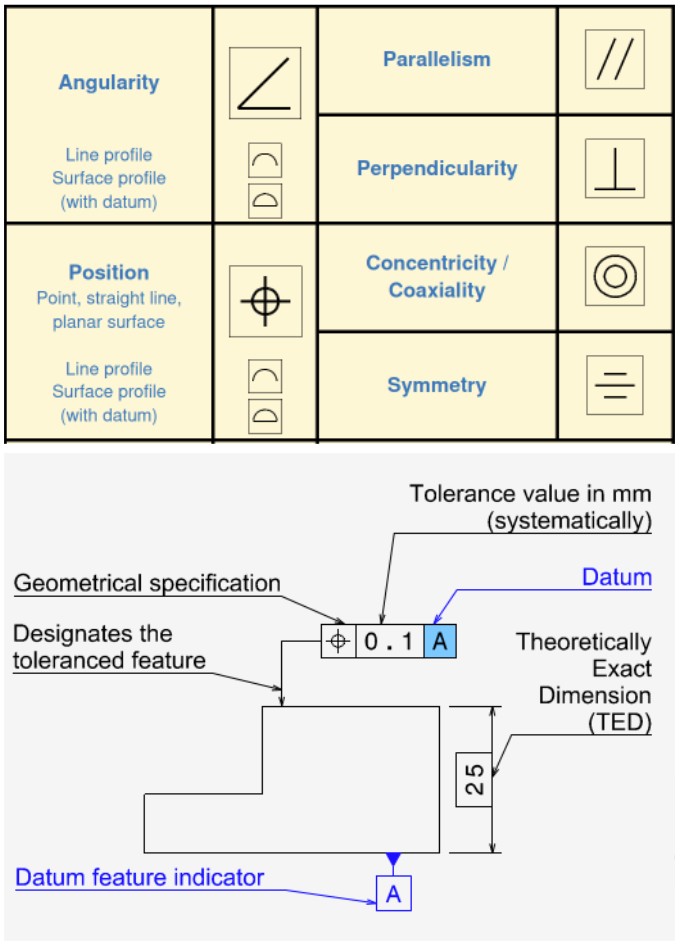

The manage page for T-Berial GD data integrates several critical functionalities designed specifically for geometric tolerance management: - Real-Time GD Symbol Mapping: Engineers upload CAD models directly, and the system automatically associates GD runs with corresponding geometry, highlighting critical features like straightness, flatness, and convergence—reducing human error in annotation. - Interactive Tolerance Visualization: Users benefit from live 3D rendering, where tolerance zones morph dynamically to show compliance across movement sequences and assembly conditions. - Regulatory Alignment Tools: Built-in checkboxes verify alignment with ASME Y14.5 standards, including nominal tolerances, datums, and feature control frames, ensuring that every annotation meets industry benchmarks.- Collaborative Workflow Hub: The portal supports shared annotations, annotation history logs, and revision tracking—critical for cross-functional teams. Teams report faster consensus on design intent than with legacy methods. - Data Export & Integration: GD data can be seamlessly exported to PLM, ERP, and simulation software, closing the loop between design, validation, and production.

How the Portal Simplifies GD—Tolerance Documentation and Tracking Documentation remains one of the most error-prone stages in GD&T execution. The manage page eliminates manual spreadsheets and scattered notes by consolidating tolerance data into a searchable, version-controlled repository. Each geometry feature is tagged with: - Tolerance value (± value) - Modifier (e.g., laminate, modify, datum extend) - Relevant GD symbol and control frame - Application conditions (positioning, orientation, movement) engineers can instantly verify whether a feature’s tolerance envelope conflicts with adjacent dimensions—a capability that traditional CAD-based annotation simply cannot replicate at scale.

In one case study, a Tier-1 aerospace supplier reduced GD-related design changes by 40% after deploying the portal, citing improved documentation accuracy and faster audit preparation.

Best Practices for Leveraging the GD Benefits Portalmanage Page To maximize effectiveness, teams should adopt structured workflows when using the portal’s GD data management capabilities: - Standardize Annotation Protocols: Train engineers to use consistent GD symbol placement and naming conventions, ensuring the portal’s search and filtering functions remain powerful. - Link Tolerance Data to Engineering Change Orders (ECOs): Every GD adjustment must trigger updates across linked documentation—only the managed page supports automated cross-references.

- Conduct Regular Portal Audits: Use the portal’s history module to verify that tolerance definitions haven’t drifted from original design intent—a critical step for compliance in regulated industries. - Leverage Automated Alerts: Configure notifications for tolerance violations or reversion to outdated GD entries, minimizing overlooked non-conforming features.

The Future of GD&T: Digital Mastery Through the GD Benefits Portal The GD Benefits Portalmanage Page for T-Berial GD data is not merely a document repository—it is a dynamic engine for geometric discipline.

As digital twin technologies and AI-driven inspection tools become integral to advanced manufacturing, this portal emerges as the cornerstone of intelligent dimensional control. By transforming abstract GD&T principles into interactive, accessible data flows, it empowers engineering teams to achieve unprecedented accuracy, reduce risk, and accelerate time-to-market. For manufacturers seeking competitive edge through tighter quality control, adopting the manage page is no longer optional—it is essential.

With its blend of usability, compliance, and scalability, the portal sets a new benchmark in how geometric standards are managed in the digital age.

Related Post

Snow Rider Io: Redefining Speed and Precision on Annual Snowmobile Rifles

Meet Sam Heughan — The Scottish Sibling Whose Charisma Birthed the Indelible Jamie Fraser

Intel Leak Gave First Glimpse of 'Battlefield 6' Next-Gen Tech

The Life And Love Of Cynthia Erivo: A Journey Woven with Resilience, Artistry, and Devotion