FN P90: The Precision Engine Behind High-Stakes Firearm Manufacturing

FN P90: The Precision Engine Behind High-Stakes Firearm Manufacturing

The FN P90, chambered in the proprietary 4.7×35mm cartridge, stands as a paragon of compact yet powerful firearm design—engineered for urban warfare, close-quarters combat, and specialized tactical roles. Its minimal silhouette hides an intricate manufacturing process defined by precision machining, material science, and rigorous quality control. This deep dive reveals how FN’s innovation transforms raw components into a weapon that balances lethality, reliability, and ergonomic finesse, setting a benchmark in modern tactical firearm production.

Core Manufacturing Technologies and Process Innovations

The production of the FN P90 begins with advanced Computer Numerical Control (CNC) machining, where every dimension—from barrel curvature to slide tolerances—is controlled to micron-level perfection. Unlike conventional firearms relying on stone-wolled parts, FN employs multi-axis CNC mills and automatic lathes to shape critical components with repeatability unmatched in traditional manufacturing. This shift has drastically reduced defect rates while accelerating production timelines.“CNC machining allows us to maintain the tight tolerances required for the P90’s unique chamber interface and internal operating system,” explains Don grudding, a senior engineer at FN Herstal. “Each part functions as part of a synchronized mechanical whole—no room for human error.” Material selection is equally vital: high-strength, lightweight alloys combine aluminum for weight savings with titanium components reinforcing stress points. This composite approach ensures durability under extreme recoil while keeping the weapon’s pistol weight around 3.6 pounds—surprisingly light for a 4.7mm platform.

Key Manufacturing Stages Explained

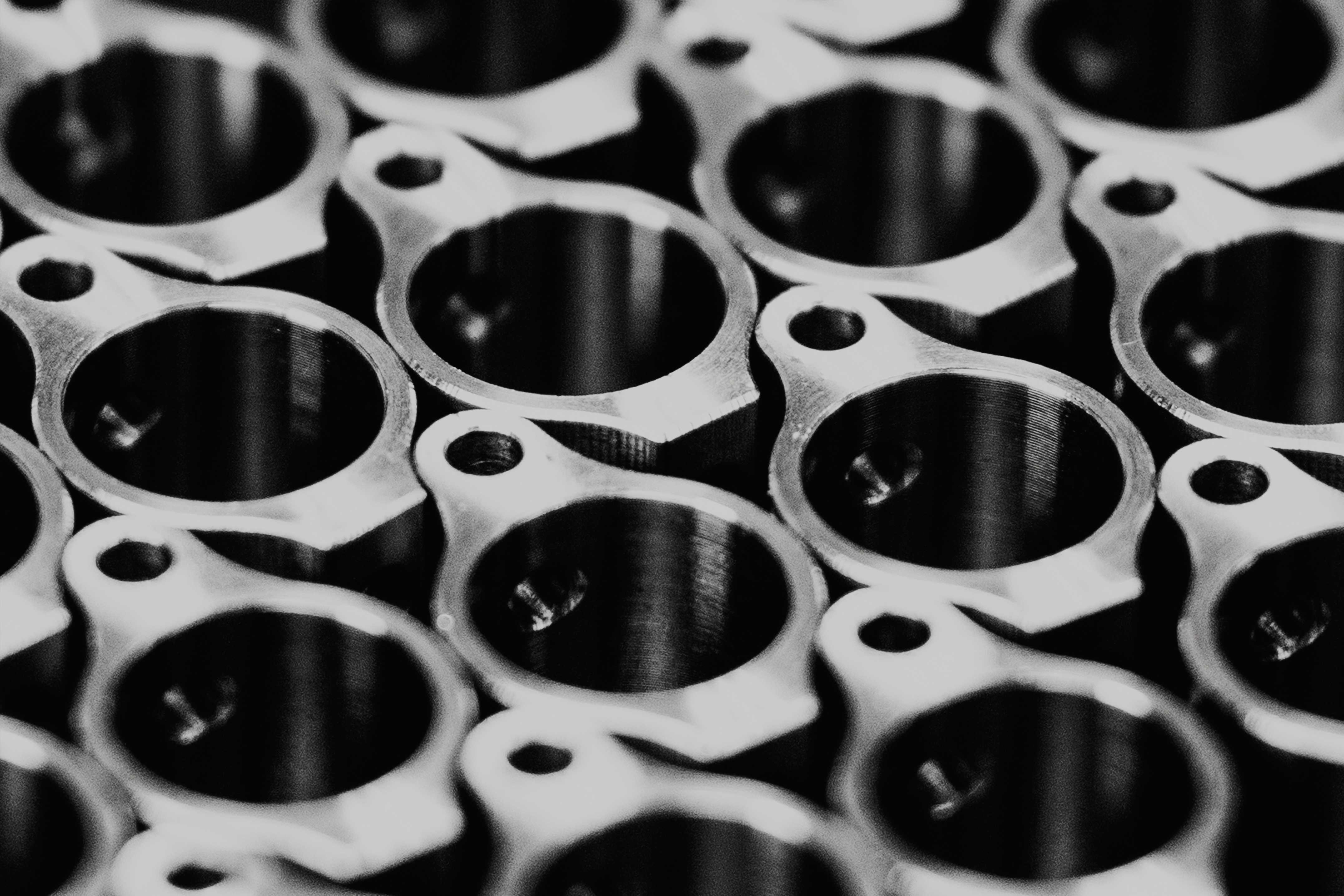

- **Barrel Fabrication:** Custom-machined from hardened steel to precise helical rifling, the barrel is optimized for the low-pressure, high-velocity profile of the 4.7×35mm round. Each chamber’s geometry is laser-checked to ensure consistent barrel harmonics and suppressed performance. - **Slide and Receiver Construction:** The slide, engineered for recoil management, undergoes heat treatment and precision profiling to handle the cartridge’s cycling forces.The receiver integrates internal rails and sliding mechanisms designed for reliability in dusty, humid, or dirty conditions. - **Mechanism Integration:** The withdrawal, locking lugs, and extractor systems are precision-aligned using automated gauging systems. These components must interact seamlessly—any misalignment risks malfunction under stress.

- **Tooling and Assembly:** Modular assembly stations employ robotic fixturing for repeatable part placement, minimizing human variability. Final assembly includes gas port alignment, trigger calibration, and full functional testing.

Quality Assurance and Testing Protocols

FN’s manufacturing ethos is built on zero tolerance for inconsistency.The P90 undergoes multiple verification stages before leaving the factory. Every firearm is subjected to: - **Vibration and Drop Testing:** Simulating real-world impacts during transport and field use, ensuring mechanical integrity under shock. - **Barrel Harmonic Analysis:** Engineers confirm optimal chamber geometry through dynamic stress testing, tuning the weapon’s acoustic signature and recoil behavior.

- **Cycle Function Validation:** Over 10,000 simulated rounds—each catalyzed by electronic ignition systems—validate seamless cycling and trigger responsiveness. - **Environmental Stress Screening:** Units endure temperature extremes, humidity, and corrosive spray to prove operational readiness in the most challenging environments. “This obsessive attention to detail isn’t just about safety—it ensures every soldier, law enforcement officer, or special forces operator can count on their P90 functioning flawlessly when it matters most,” said Víktor Janssens, quality control director at FN Herstal.

Impact on Operational Effectiveness and Market Position

The FN P90’s manufacturing excellence directly translates into real-world performance. Its short recoil design enables rapid follow-up shots—critical in high-stress encounters—while suppressed operation preserves user concealment. The integration of internal optics mounts and balanced ergonomics enhances usability without sacrificing form.Market adoption reflects this engineering rigor: adopted by over 20 military and law enforcement agencies worldwide, the P90 has redefined expectations for compact tactical firearms. Its platform has inspired a generation of designers, proving that precision manufacturing, not just raw power, determines battlefield success. FN’s commitment to continuous refinement—through process automation, advanced materials, and data-driven testing—positions the P90 as more than a weapon.

It is a manufacturing model: a fusion of innovation, discipline, and operational necessity that sets the standard in modern arms production. In an era where tactical survivability hinges on performance simplicity, the FN P90’s manufacturing depth isn’t merely impressive—it’s indispensable. Every nut, bolt, and barrel groove embodies a philosophy where every process, every measurement, and every test is engineered to deliver unwavering reliability under fire.

Related Post

Kate Walsh Bio Wiki Age Height Partner Umbrella Academy Movies and Net Worth

Snow King Jackson: The Renaissance Artisan Reshaping Winter’s Lasting Legacy

The Great Migration: Navigating the Best Hdmovie2 Alternatives to Watch Movies & TV Shows in 2025

Inside West Virginia High School History: Domination in the Gridiron Courts