Flip On Long or Short Edge: Master the Edge-Granting Precision Shaping Every Craft and Car

Flip On Long or Short Edge: Master the Edge-Granting Precision Shaping Every Craft and Car

In an industry where form meets function, the Flip On Long or Short Edge technique stands as a fundamental yet transformative skill—essential in woodworking, metal fabrication, design, and tactical gear customization. This precise method enables craftsmen and consumers alike to tailor the completion of materials and components with accuracy, enhancing both aesthetics and structural integrity. Whether finishing a workbench edge, modifying a tactical knife, or enhancing furniture detail, knowing when to flip long or short determines the outcome’s quality and longevity.

The technique hinges on understanding material behavior and intended use, coupled with the right tools and technique execution. From coarse power flipping to fine hand finishing, mastering edge orientation is not just a mechanical action—it’s a calculated decision rooted in practical craftsmanship.

Defining the Edge-Flipping Paradigm: Long vs.

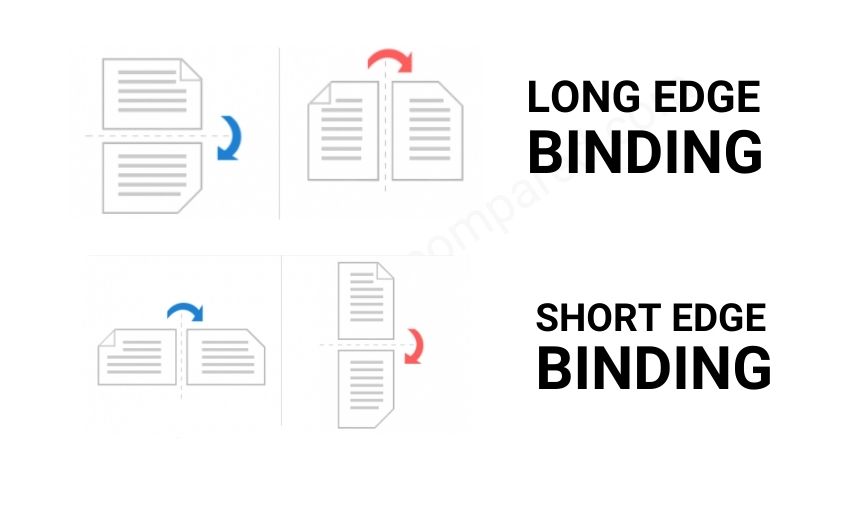

Short The distinction between long and short edge flipping is subtler than it appears. Each approach serves distinct purposes shaped by the material, tool, and end goal. Long-edge flipping typically extends along the full length or a significant portion of a segment—ideal for securing stability, enhancing durability, or creating clean, predictable profiles.

It is commonly used in woodworking for mantle surround edges or in metalworking for reinforcing weld seams. In contrast, short-edge flipping involves working only a fraction of the edge—usually a few centimeters—allowing for dramatic visual texture, precise control, and selective reinforcement. This approach shines in artisanal designs, custom hardware, and marked-up consumer accessories where subtle touches define the user experience.

The choice between long and short isn’t arbitrary; it determines not just the sensory outcome but also the structural performance and ease of finishing. "Flip long when you need a stable, gap-free edge," advises master cabinetmaker Elena Torres, "flip short when subtle character makes the piece unique."

Long Edge Flipping: The Foundation of Integrity and Strength

Long-edge flipping is the cornerstone of robust fabrication. By engaging the full or extended length, this method reinforces joints, minimizes stress concentrations, and ensures seamless continuity—especially critical in high-load applications like tabletops, workstations, or structural metal frames.- Structural reinforcement: Whole-edge engagement distributes pressure evenly, reducing chipping and flex over time.

- Precision alignment: Long flipping creates parallel, consistent lines—vital in joinery and paneling.

- Tool compatibility: Saws, miters, and rotational edge tools handle long flipping efficiently, ensuring smooth transitions without excessive deflection.

Examples of long-edge flipping abound in traditional furniture: seamless mitered corners, flush oversized tabletops, and trim edges where tight, repeatable profiles elevate both visual quality and longevity.

Short Edge Flipping: Artistry and Individuality

While long flipping builds strength, short flipping opens doors to creativity and customization.By limiting engagement to short segments—sometimes mere inches—crafters sculpt deliberate textures, accentuate hand features, or highlight focal points. This technique thrives in decorative elements, hand-forged tools, and bespoke hardware where visual definition drives value.

In knife making, skilled artisans flip short edges to create distinctive grinds with finely alternated bevels—each flip a deliberate brushstroke.

Similarly, in cabinetry, partial flips define drawer fronts or cabinet rails, adding rhythm and handmade charm without compromising function. Short flipping demands greater manual control and toolmanship, as small working zones limit margin for error. “Success depends on steady hands and precise tool paths,” notes metal artisan Mia Reed.

“Each flip must be intentional—routing, sanding, or thermal treatment becomes part of the narrative.”

Tools, Techniques, and Industry Insights

Mastering either long or short edge flipping requires a layered toolkit and methodical approach. Power tools dominate production settings—router tables, edge banders, oscillating tools, and CNC nesters—each optimized to handle defined flips with consistency. For handwork, chisels, knives, REEDS--FLIP (analog flipping jigs), and hand planers enable exacting control.Recent industry shifts highlight a growing fusion of traditional craftsmanship and digital precision. “Computer-assisted flipping allows repeatability once reserved for mass production,” explains Greg Lin, leader of a precision manufacturing firm. “But seasoned crafts still rely on tactile feedback—you feel the grain, heat, and resistance to decide where and how to flip.” Technique refinements remain central: maintaining consistent pressure, selecting appropriate tool paths, and aligning edge transitions prevent common flaws like chatter marks, uneven wear, or incomplete engagement.

Trial-and-error remains crucial, particularly when combining materials—wood to metal, or ceramic to steel—where thermal expansion or hardness differences affect flip outcomes.

Common Pitfalls and How to Avoid Them

Even experts encounter challenges. One frequent error

Related Post

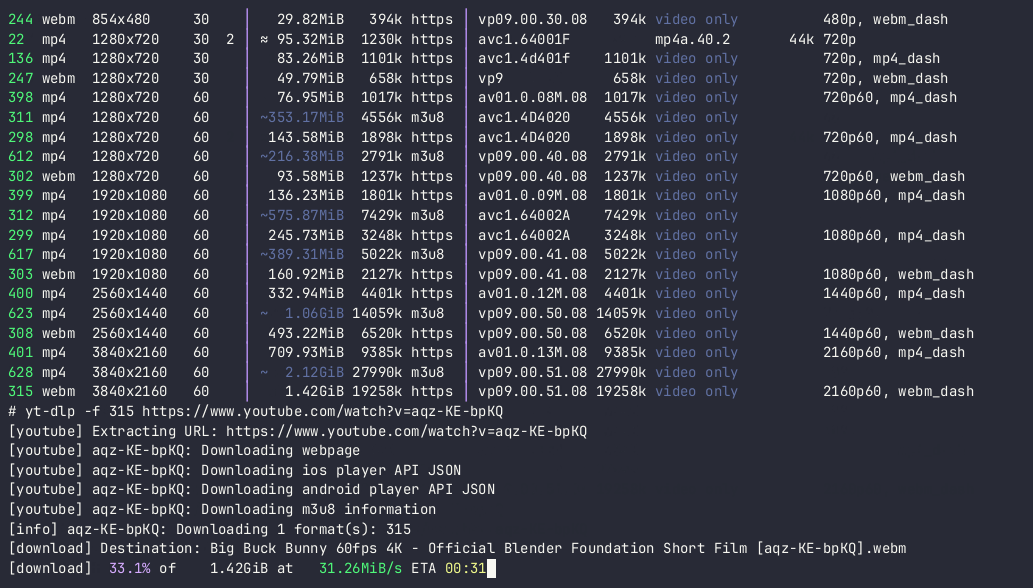

Yt Dlp Your Guide to Mastering the Versatile Download Manager for Uninterrupted Media Capture

Mikhaila Petersons Husband All About Andrey Korikov

Dissecting the Npple Slip: The Communal Event Under the Scope

How 99Math Logo Transforms Learning Through Visual Precision and Algorithmic Clarity