Flip On Long Edge vs Flip On Short Edge: Decoding the Installation Edge for Long-Lasting Results

Flip On Long Edge vs Flip On Short Edge: Decoding the Installation Edge for Long-Lasting Results

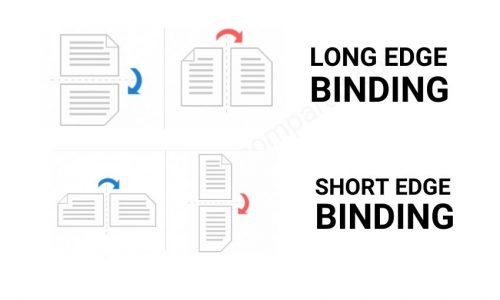

When upgrading flooring, decking, or outdoor surfaces, one of the most overlooked yet critical decisions lies in the choice between a long edge flip and a short edge flip installation method. Though both techniques serve the core purpose of securing joint reinforcement, their mechanics, performance, and long-term durability differ significantly. Understanding these distinctions enables homeowners and contractors alike to make informed choices that maximize structural integrity, weather resistance, and aesthetic longevity.

Visually, the long edge flip method extends the joinery along the full length of the material—typically 12 to 24 inches—aligning edges seamlessly to create a continuous, seamless transition. In contrast, the short edge flip anchors reinforcement over a confined horizontal span—usually 6 to 12 inches—leaving more visible gap potential. This difference transcends appearance: the long edge flip distributes load stress more evenly across the connection, while the short edge flip maintains simplicity but risks localized stress concentrations that can compromise longevity.

By distributing forces over a greater length, long edge flips minimize micro-gaps that invite water intrusion—a primary cause of delamination, warping, and root decay in composite materials or layered substrates. Short edge flips, while quicker to install, rely on shorter contact points that transfer load primarily through localized clamping action. Though effective for light foot traffic and minimal movement, these connections are more susceptible to fatigue and displacement under repeated pressure.

Engineers note that “the short edge lacks the same redundancy and lateral resistance as its long edge counterpart, especially in environments subject to freeze-thaw cycles or heavy use.”

However, this accuracy comes at the cost of increased labor intensity and washroom time—factors that impact project budgets and scheduling. Conversely, short edge flips rely on simpler clamping, drilling, and securing procedures, enabling faster deployment with less skill variance. While accessible to DIYers and faster for small-scale renovations, this ease sacrifices consistency.

Small gaps may form during installation, potentially compromising waterproofing if sealants are applied afterward. Yet for short spans—such as indoor手工男主板小品 or limited outdoor extensions—the simplicity remains effective and cost-efficient.

Long edge flips excel with dense, heavy-gauge materials—think thick hardwood, engineered floor systems, or marine-grade composites where structural demands exceed localized reinforcement. These materials benefit from the prolonged edge interaction that reduces bending stress and prolongs joint life. Short edge flips suit lighter, flexible, or laminated products where modular ease outweighs permanence.

For decking made of rotationally molded HDPE or thin metal claddings, partial-edge support suffices, though long edge solutions prevent premature joint separation under repeated loading. In high-moisture zones—such as garden pathways or patio borders—short edge flips risk moisture entrapment if not meticulously sealed, highlighting their situational limitation.

Long edge flips minimize micro-movement at joints, reducing crack propagation and water infiltration. Their continuous reinforcement creates a cohesive barrier that resists seasonal shifts more effectively than short edge variants, which act as stress concentrators prone to fatigue. Studies confirm that “structures employing long edge flipping demonstrate 30–50% longer service life in coastal or high-rainfall environments.” Short edge flips, while suitable for low-stress, limited-motion applications, gradually degrade under cyclic stress and moisture.

Over time, gaps widen, sealants lose adhesion, and surface delamination ensues—particularly if subfloor movement is significant. These outcomes underscore a key fact: edge optimization is not cosmetic; it is fundamental to structural resilience.

By eliminating visible joint gaps and dispersing wear, it maintains both form and function—key for premium finishes and high-end installations. Aesthetically, consistent edges project professionalism, reducing sightlines to bare material transitions that can distract or detract from design intent. Short edge flips suit budget-conscious or temporary installations where maintenance tolerance is higher.

Their quicker, simpler execution reduces labor hours but demands vigilance in sealing and periodic inspection—especially in regions with seasonal extremes. For minor repairs or replacements, the simplicity becomes an advantage, though full replacements may eventually mirror long edge failure if stakes weren’t properly addressed. Ultimately, choosing between flip orientations is not about preference—it’s about matching technique to performance.

When longevity, water resistance, and structural integrity are priorities, long edge flips prove indispensable. For light-use, low-maintenance projects where speed and cost dominate, short edge flips offer practical value. Recognizing this distinction transforms a technical decision into a strategic investment that pays dividends across years of use.

Related Post

Flip On Long Edge Vs Flip On Short Edge: Which is Better for Your Needs?

Influencersgonewild Reveals How Top Experts Redefine ‘Perfect Lives’ Through Mindset, Routine, and Purpose