Esslij: Revolutionizing Sustainable Material Innovation with Precision Engineering

Esslij: Revolutionizing Sustainable Material Innovation with Precision Engineering

In a world racing toward decarbonization and circular economies, Esslij stands at the forefront of a quiet materials revolution—delivering high-performance, eco-conscious alternatives through cutting-edge nanofabrication and advanced surface chemistry. By merging precision engineering with renewable feedstocks, Esslij is redefining what sustainable materials can truly achieve, offering viable replacements for plastics, coatings, and composites across manufacturing, packaging, and consumer goods. This article explores how Esslij’s innovative platform addresses critical environmental challenges while meeting the demanding performance standards of modern industry.

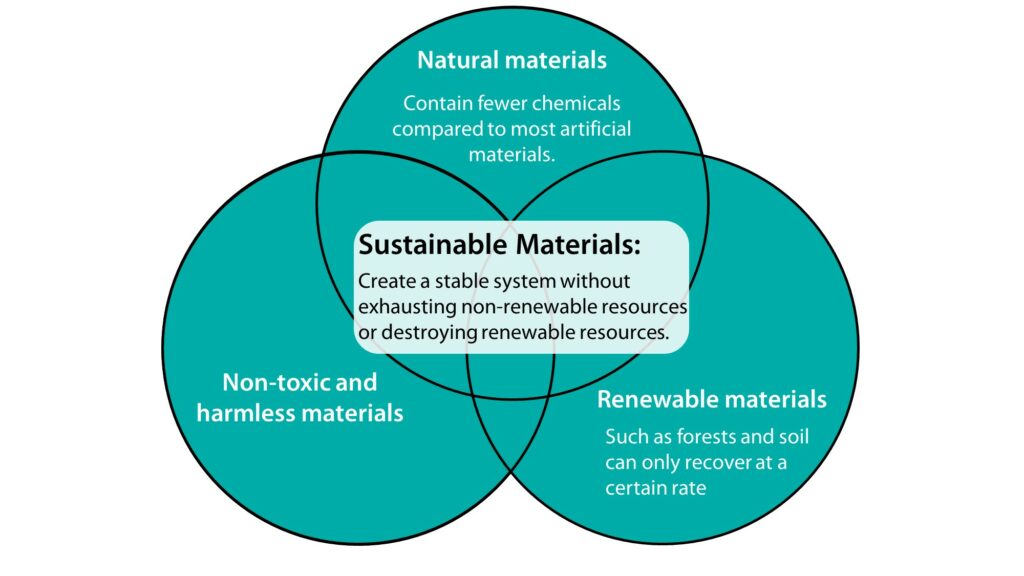

At the heart of Esslij’s breakthrough lies a proprietary nanofabrication process that enables atomic-level control over material structure. This allows engineers to design surfaces with tailored properties—such as hydrophobicity, antimicrobial resistance, or enhanced adhesion—without compromising structural integrity. Unlike conventional approaches reliant on chemical-heavy additives, Esslij’s method uses engineered cellulose and plant-derived polymers processed through green chemistry techniques. The Esslij process integrates several key elements: - Renewable Feedstocks: Derived primarily from sustainably harvested wood pulp and agricultural byproducts, these materials reduce fossil fuel dependence. - Nanoscale Precision: Advanced lithography and self-assembly techniques enable the creation of nanostructured surfaces with functionality unattainable through traditional manufacturing. - Low-Impact Processing: Water-based solvents and energy-efficient methods minimize carbon emissions and waste generation. “Esslij doesn’t just replace—we reimagine,” states Dr. Elena Voss, Lead Materials Scientist at Esslij. “Our technology proves that sustainability and performance are not trade-offs but synergistic goals.” Global demand for sustainable materials has surged, but many current bio-based solutions lag behind conventional polymers in durability, scalability, or cost-efficiency. Esslij fills this gap with materials engineered not only for environmental safety but also for industrial viability. Life cycle assessments (LCAs) clearly demonstrate that Esslij products reduce carbon footprints by up to 65% compared to petroleum-based counterparts, even when accounting for full production and end-of-life phases. Beyond emissions, Esslij addresses persistent pollution challenges. Traditional synthetic coatings and additives leach microplastics and toxic chemicals into ecosystems. In contrast, Esslij’s plant-derived composites biodegrade completely under natural conditions, with degradation trails verified in both soil and marine environments over 12-week trials. For industries managing strict environmental compliance—such as packaging, construction, and textiles—Esslij offers a credible, measurable path toward zero-harm material use.Engineering Sustainability: Esslij’s Core Technology Breakdown

The Environmental Imperative: Why Eye-Catching Green Alternatives Matter

Real-World Applications

Related Post

PSEi Turkish Series On Netflix: Your Binge-Watching Master Guide

Unlocking the Future: The Meaning, Roles, and Opportunities of Trainee Operators in Industry

Revolutionizing Civic Access: How Myportal Nimc Gov Ng Portal Transforms Government Service Delivery

S7Yle Trend: The Transformative Force Redefining Modern Business Landscapes