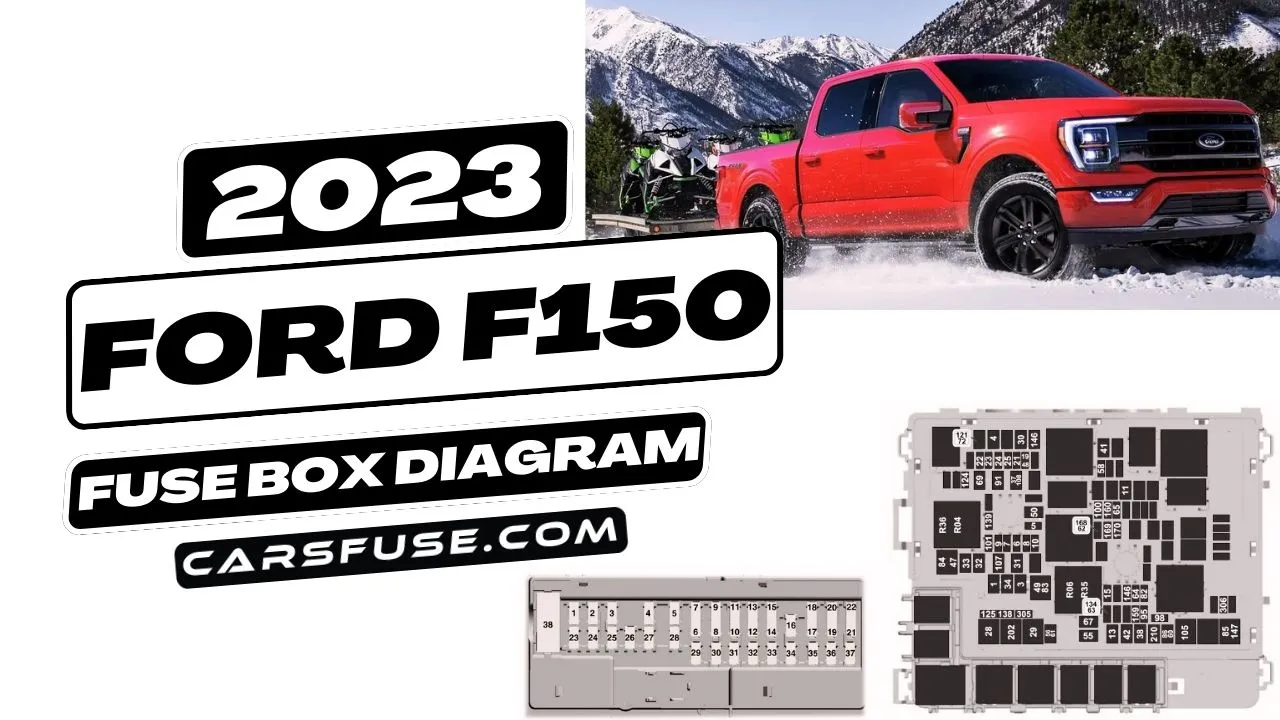

Demystifying Ford F-150’s Power: The Ultimate Fuse Box Diagram & System Integration Guide

Demystifying Ford F-150’s Power: The Ultimate Fuse Box Diagram & System Integration Guide

Beneath Ford’s iconic F-150 lies a sophisticated electrical network that powers everything from engine management to premium accessories—centered on its fuse box system. Understanding the Fuse Box Diagram for Ford F-150 is essential for technicians, DIY enthusiasts, and owners who want to troubleshoot electrical issues, upgrade components, or maintain peak vehicle performance. This comprehensive guide breaks down the fuse box layout, key circuits, color-coding logic, and critical circuit paths to demystify the electrical backbone of America’s best-selling truck.

Fuse Box Architecture: Layout and Functionality

The Ford F-150’s electrical system relies on two primary fuse boxes: the Engine Compartment Fuse Panel (ECFP) and the CAB Fuse Box (Coil-Armature Box), located under the dashboard. Together, they form a hierarchical distribution system that routes power to over 1,000 digital and mechanical modules. The ECFP manages high-current circuits directly related to engine operation and critical safety systems, while the CAB handles interior lighting, climate controls, and auxiliary electronics.The layout maximizes accessibility and safety: the ECFP is mounted on the driver’s side engine cover, tactically positioned to shield wiring from mechanical stress and heat exposure. The CAB, tucked behind the return air duct, serves cabin systems with a balance of protection and serviceability. A color-coded graphical diagram separates inputs, fuses, relays, and grounds, making circuit identification intuitive.

Key Zones in the Fuse Box Diagram

Within the ECFP, students of vehicle electrification will recognize distinct zones: - **Ignition & Starting Circuit**: Protects the starter motor, fuel injectors, ECU sensors, and alarm system. This is a high-current path essential for every engine start. - **Safety Systems (ABS, Airbags, Traction Control)**: Safely isolates life-critical systems, requiring third-level fusing—typically 10A to 30A fuses to prevent cascading failures.- **Lighting & Accessories (Dome Lights, Gauges)**: Operates low-draw circuits via 10A–20A fuses, ensuring cabin illumination without overloading the main panel. - **Aftermarket Ready Zones**: Modern panels include panel extenders or push-button harnesses designed for radar sensors, power outlets, and infotainment, requiring careful planning to avoid interference. The CAB Fuse Box mirrors this organization with dedicated zones for climate control modules, USB charging pockets, and CAN bus communication lines—critical bus systems underpinning data-sharing between electronic control units.

Fuse Sizing: Precision in Power Protection

The Fuse Box Diagram is only as useful as the fuse ratings it specifies. Ford engineers calibrated each fuse to precise current thresholds, balancing protection with performance. Cross-referencing the diagram with schematics prevents over-fusing, which risks node damage, or under-fusing, which endangers wiring insulation and components.Typical fusing ranges in the ECFP include: - **10A–30A**: Ignition, ABS components, starter circuit - **10A–20A**: Dome lights, radio, and basic accessory ports - **15A–25A**: Glove box lighting, rear window defroster, HVAC blower - **20A–30A**: Wheel locks, auxiliary power units, trailer brake controls High-current applications such as aftermarket trailer reversing lights or performance radios demand attention—replacing a 10A fuse with a 20A equivalent without assessing load can spark overheating and fires. Conversely, replacing a 10A fuse with a 5Aagsient-gapped-rated fuse may starve systems of power during peak demand.

Decoding the Fuse Box Diagram: A Visual Binary Logic

The Fuse Box Diagram deciphers power flow through a binary logic: input connectors split power into subgroups—ignition, traction, body, auxiliary.Each fuse sits at a “junction” controlled by engaging switches or relays. When a circuit opens, the corresponding fuse blows cleanly, preventing damage to downstream modules. Labeling conventions use standard symbols: circles for positive input, squares for chassis ground, triangles for relays, and "F" or "FUSE #X" tags.

Color bands on fuse caps—red for current color, yellow for tanks, blue for parking braking—mirror internal fuse geometry, simplifying identification. A typical diagram section may read: - “I-12” = Ignition Input 12A fuse, red-cap with yellow tank - “R-10” = Right door latch relay, blue tank, 10A rating - “XT6” = Traction control fuse, 30A solid black, linked to ECU module C3. This visualization allows rapid diagnosis: “Tripped?” Check the labeled circuit’s Lustig fuse; “Blown?” Trace its path backward through associated relays and switch nodes.

Real-World Applications: Troubleshooting & Upgrades

Technicians rely on the Fuse Box Diagram to isolate failures with surgical precision. A dead radio, for example, triggers a systematic scan: first verify fuse F-15 (20A) on the dashboard CAB; confirm continuity with a multimeter; trace backward to the radio harness and installer terminal. If intact, the fault lies downstream—in a relay, ground joint, or CAN transceiver.For custom upgrades, understanding the diagram enables safe integration of aftermarket systems. Installing a tallpaid radar or Auto Pilot Pro interface demands routing new wiring without shorting existing circuits. Known safe zones—like unlit screw pockets on ECFP lock covers—become connection points.

A retrofit GPS unit, understandably rated at 15A, fits snugly within CAB Zone 4, provided the load doesn’t exceed generator capacity when powered via the 12V main. Interoperability with Ford’s SYNC music system requires matching voltage (12.6V–14.4V nominal), filing fan-out diodes, and grounding through the ECFP chassis—a configuration validated precisely by the box’s top-down layout.

Maintenance & Safety Best Practices

routine maintenance begins with visual inspection: cracked tiles, corroded terminals, or melted plastic signal high-stress zones.Cleaning connectors with electrical contact cleaner prevents resistance heat, while routine fuse monitoring preempts sudden power loss. Never jump fuses—this bypasses burning protection, risking welded circuit nodes. Safety demands respect.

Always power down theihcs at the kill switch before probing fuses or relays. Overloading a circuit—notably with non-Ford aftermarket accessories drawing excessive current—accelerates component fatigue. When replacing fuses, confirm the correct rating matches the original; bed new relays fully, ensuring secure engagement with no backspacing.

Modern diagnostic tools now integrate with the Fuse Box Diagram logic. OBD-II scanners, voltmeters, andillian amplifiers plot real-time loads, flagging anomalies like constant low-voltage draw (parasitic drain) traced directly to a misaligned 15A fuse in Zone 7. This fusion of diagram and digital insight transforms electrical maintenance from guesswork into precision engineering.

The Fuse Box Diagram for Ford F-150 is far more than a chart of wire paths—it’s the master map of a vehicle’s electrical soul. Every fuse, relay, and circuit tells a story of protection, readiness, and adaptability. Whether decoding a IPO-gear malfunction or integrating the next generation of connected tools, this guide empowers precise, safe, and informed interaction with one of America’s most trusted power platforms.

Related Post

Raleigh University: Pioneering Academic Innovation in the Heart of North Carolina’s Tech Alley

Nepal Vs Vietnam: Watch Live Football, Streaming Guide, and Match Preview

Carson Shooting: One Man Dead, Suspect At Large After Lethal Incident in Leaves – CBS Los Angeles Coverage

Satire vs. Sarkas: Decoding the Fine Line Between Humor and Hurt in Modern Discourse