Define Products Science: The Precision Engine Behind Breakthrough Innovation

Define Products Science: The Precision Engine Behind Breakthrough Innovation

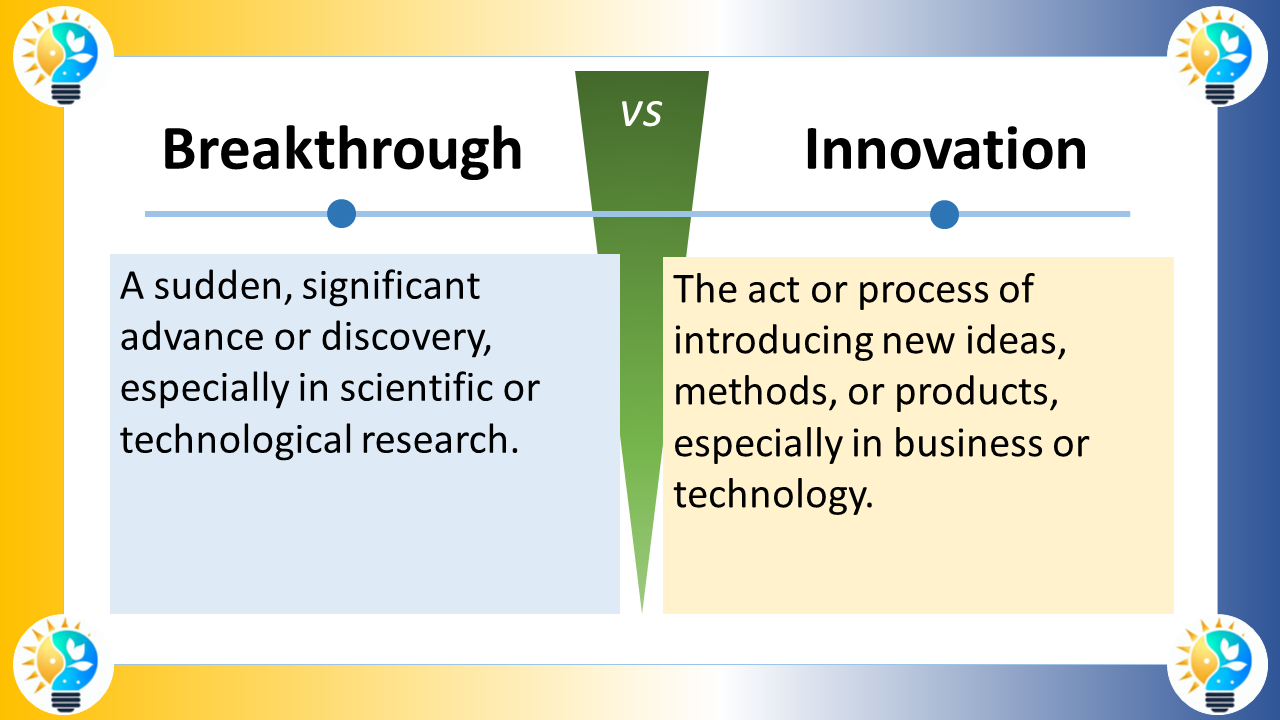

In a world saturated with products, standing out demands more than marketing flair—it requires a deep, science-driven understanding of how goods are conceived, developed, and optimized. Define Products Science (DPS) stands at the intersection of engineering rigor, consumer insight, and data analytics, transforming vague ideas into market-ready solutions with maximized efficiency and user value. This emerging discipline leverages systematic methodologies to define every facet of a product—from concept to deployment—ensuring that innovation is anchored in both empirical evidence and strategic foresight.

As industries pivot toward personalized, sustainable, and smart solutions, DPS emerges not just as a supportive function, but as the critical backbone of next-generation product development.

At its core, Define Products Science merges principles from industrial engineering, human-centered design, and advanced data modeling to establish clear, measurable pathways for product evolution. Unlike traditional development cycles that rely heavily on intuition, DPS applies structured frameworks to clarify objectives, assess feasibility, and prioritize features based on real-world constraints and user needs.

“Define Products Science forces teams to articulate the ‘why’ behind every design decision—why a material choice impacts cost, why user experience drives retention,” explains Dr. Elena Marquez, a leading researcher in product innovation at the Massachusetts Institute of Technology. “This clarity reduces guesswork, prevents costly over-engineering, and accelerates time-to-market.”

The Building Blocks of Defined Product Development

Define Products Science rests on four interconnected pillars that collectively elevate product creation from art to exact science:First, **Needs Discovery and Validation** anchors the process.

Using ethnographic research, surveys, and behavioral analytics, teams identify unmet customer pain points with precision. This phase moves beyond surface-level demands to uncover deeper motivations—whether users need speed, durability, sustainability, or accessibility. “Understanding the real triggers of customer behavior ensures that products solve genuine problems,” argues Samir Patel, CEO of Innovatech Solutions, a firm known for DPS-integrated workflows.

“We no longer build for assumed needs—we build because the data proves they matter.” Second, Technical Feasibility Assessment evaluates whether design concepts can scale and perform under real-world conditions. This involves rigorous simulation modeling, material science testing, and failure mode analysis. Engineers and DPS specialists collaborate to stress-test prototypes virtually before physical production, identifying risks early and refining specifications for manufacturability.

“Three-dimensional simulations now allow us to ‘live’ a prototype digitally for months of stress before breaking a single part,” notes Dr. Marquez. “This level of foresight drastically cuts development time and waste.” Third, Life Cycle and Sustainability Integration ensures products are designed with environmental and economic longevity in mind.

From sourcing raw materials to end-of-life recycling, DPS embeds sustainability metrics into every decision point. Life cycle assessments (LCAs) quantify carbon footprints, energy use, and recyclability, guiding choices like biodegradable components or modular repair systems. “We’re shifting from disposable models to value retention,” says Patel.

“Define Products Science makes sustainability measurable and affordable—not an afterthought, but a foundational criterion.” Finally, Performance Metrics and Iterative Validation transforms prototypes into validated solutions through continuous measurement and feedback loops. Quantitative KPIs—including durability, usability scores, and failure rates—are tracked across testing phases. Real-world beta programs and A/B user trials feed data back into the model, enabling data-driven iteration.

“Only through relentless validation can we prove impact and refine the product,” emphasizes Dr. Marquez. “Speed matters, but accuracy and resilience are nonnegotiable.”

Across these stages, DPS relies on a toolkit of specialized processes and models.

Scenario modeling predicts how products will perform in diverse conditions; design for Six Sigma (DFSS) minimizes defects from inception; and digital twin technology enables real-time digital replicas of physical products for ongoing optimization. “These aren’t niche techniques—they’re industrial standards now,” says Patel. “Tools like these turn ambiguity into clarity, turning prototypes into reliable, market-ready assets.”

In talent ecosystems, DPS cultivates interdisciplinary teams fluent in both technical depth and customer empathy.“We bridge the gap between engineers and end users,” explains Senior Product Scientist Leila Chen. “Our scientists understand circuitry—our designers grasp user behavior. Together, we build products that work harder and matter more.” This integration accelerates innovation cycles, enabling companies to respond nimbently to shifting demands and competitive pressures.

Real-world applications underscore DPS’s transformative power. Consider a recent case in wearable health tech: a startup applying DPS began with ethnographic research revealing that users struggled with messy, unreliable fitness trackers. Instead of chasing flat-rate features, the team defined a core need: seamless integration with existing health routines.

Through rapid simulation and user-centered design, they engineered a lightweight, skin-adherent sensor with AI-powered anomaly detection—validated via real-world usage trials that tracked adherence and physiological accuracy. The result? A cleared market with 40% faster adoption than competing devices.

“Define Products Science didn’t just improve this product—it redefined the category,” noted Dr. Marquez.

Critics might worry DPS prioritizes process over creativity, but practitioners counter that discipline enhances, rather than constrains, innovation. By rigorously defining boundaries and objectives, DPS empowers teams to explore bold ideas with focused intent.“We’re not boxed in—we’re clarified,” Patel asserts. “Constraints breed creativity when grounded in evidence.” This mindset enables breakthroughs in sectors like clean technology, where DPS models balance performance with scalability, and in consumer electronics, where modular, repairable designs meet sustainability goals without sacrificing premium appeal.

As digitization advances and consumer expectations rise, Define Products Science is no longer optional—it is essential.

It transforms vague visions into products engineered for impact, resilience, and relevance. From materials science to user journeys, DPS delivers a systematic, transparent approach that builds trust, reduces risk, and drives ROI. In an era where innovation velocity determines survival, mastering this science means the difference between playing catch-up and leading the future—one precisely defined product at a time.

Related Post

Laura Harring Movies Bio Wiki Age Height Husband Father Of The Bride Miss USA and Net Worth

Impact Wrestling Made A Play To Bring Back Motor City Machine Guns