Cone Volume: The Geometry of Efficiency and Precision in Engineering and Design

Cone Volume: The Geometry of Efficiency and Precision in Engineering and Design

In an age defined by rapid innovation and exacting performance standards, the cone volume stands as a cornerstone of efficient design across industries—from aerospace and automotive to manufacturing and pharmaceuticals. Unlike arbitrary shapes, the cone volume offers a mathematically optimized structure that maximizes storage, enhances airflow, and ensures structural stability where needed. This precise use of conical geometry isn’t just theoretical—it underpins real-world solutions that balance form, function, and material efficiency.

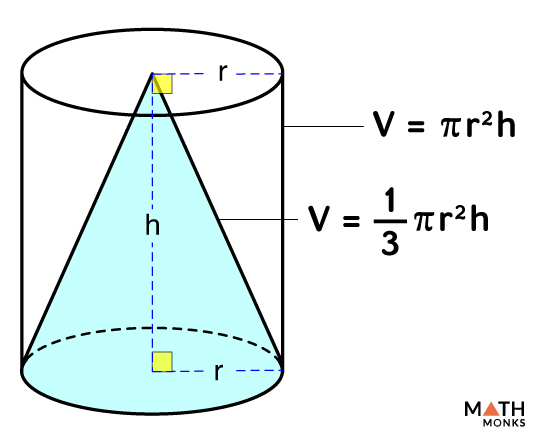

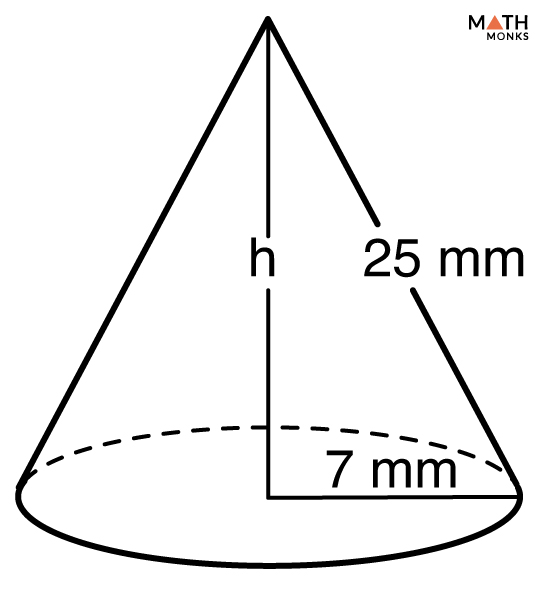

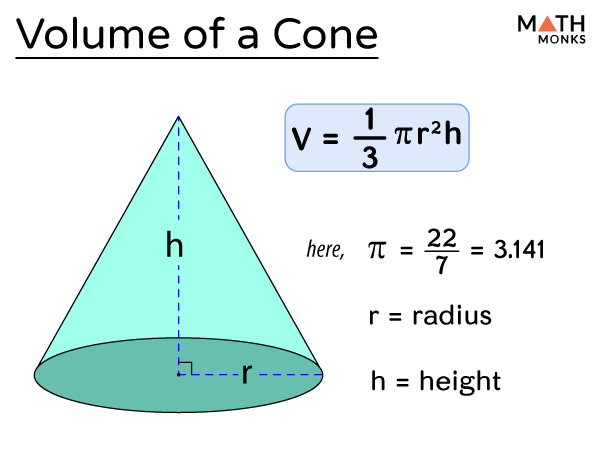

At its core, cone volume refers to the three-dimensional space enclosed within a cone—a solid with a circular base that tapers smoothly to a point called the apex. The volume of a cone is defined by the formula V = (1/3)πr²h, where r represents the radius of the base and h the height from base to apex. This ratio of one-third the base area times height establishes a fundamental efficiency principle: cones pack high capacity within limited footprints.

For example, conical tanks in chemical plants store liquids compactly while minimizing structural material—cutting costs without sacrificing durability. The small cognitive hook: unlike cubic containers, conical geometry naturally resists pressure concentration and distributes stress evenly, making it indispensable in high-load applications.

Several cone volume types guide engineering choices, each tailored to specific operational needs.

Right circular cones dominate standard design due to their symmetry and predictable stress distribution. Tapered cones—wider at the base—optimize gravity-assisted flow in systems like grain silos and sewage systems, where controlled discharge prevents blockages. Irregular or segmented cone volumes appear in architectural features such as domed roofs and sculptural installations, where aesthetic form meets calculated load-bearing capacity.

“The cone is nature’s answer to efficient space utilization,” notes Dr. Elena Marquez, structural engineer at the Institute for Advanced Manufacturing. “Its geometry balances internal volume with minimal surface area—an engineering ideal embodied in every properly sized funnel or rocket nozzle.”

Beyond static storage, cone volume plays a pivotal role in fluid dynamics and aerodynamics.

Nozzle design, for instance, relies on converging-cone configurations to accelerate gas and liquid streams with minimal turbulence. Aircraft propulsion systems use precisely engineered conical diffusers to manage airflow, reducing drag and improving engine efficiency. In HVAC systems, conical ducts regulate airflow patterns to enhance thermal distribution while maintaining compact installations.

“The cone’s angular geometry allows seamless transitions in fluid paths,” explains mechanical engineer James Tran. “This reduces energy loss and ensures smoother operation—critical in energy-sensitive environments.”

Material economy is another key advantage. Compared to equivalent-volume cubes or cylinders, cones use less material to achieve the same capacity, without sacrificing strength.

This material efficiency drives adoption in sustainable design. Green architects employ conical volumes in energy-efficient buildings—domes channel solar heat naturally, while conical skylights maximize daylight penetration, reducing reliance on artificial lighting. In packaging, collapsible cone-shaped containers minimize wasted space during shipping, lowering transportation emissions.

As global demand for sustainable solutions grows, cone volume emerges not just as a geometric choice but as a strategic tool for conservation.

Yet, challenges remain. Designing functional cone volumes demands precision: improper ratios can cause buckling under load or inefficient flow.

Manufacturing tolerances must be tight to prevent stress concentrations, particularly in high-temperature or high-pressure applications. Advanced computational modeling—such as finite element analysis—now enables engineers to simulate cone volume performance under real-world conditions, optimizing geometry for strength, flow, and durability before physical production. This digital integration of geometry and data marks the next frontier in cone volume utilization.

Real-world applications illustrate the versatility and impact of cone volume. In the automotive sector, cone-shaped fuel tanks maximize center of gravity control, improving vehicle stability. In medicine, conical biopsy needles deliver tissue samples cleanly with minimal trauma.

Industrial sieves use tapered cone volumes to efficiently separate granular materials by size. Each use case reflects a deep understanding of how cone geometry enhances effectiveness.

In aerospace, cone volume isn’t just about storage—it shapes performance.

Rocket nozzles use elliptical-conical throats to expand exhaust gases efficiently, converting thermal energy into thrust with maximum efficiency. Even spark plugs incorporate miniature conical cores to optimize ignition plasma formation, reducing engine misfires and improving fuel combustion. Here, cone volume transcends geometry to become a performance multiplier—where every cubic millimeter counts.

The cone volume’s enduring relevance stems from a simple truth: geometry that works with nature’s forces outperforms brute-force designs. By embracing the cone, engineers unlock efficiency, resilience, and elegance. Whether storing chemicals, accelerating jet engines, or distributing light, the cone volume remains an indispensable force in modern design.

Its precise proportions, refined through centuries of application, continue to drive innovation across sectors—proving that in the language of efficiency, the cone is unbeatable.

Related Post

Freddie Highmore: From Boy Star to Jason Bourne — The Unbreaking Arc of a Versatile Prodigy

Here Is The Real Meaning Behind Erome Android 6: How a Simple OS Update Ignited Cultural and Technological Shifts

A Warning You Need To Hear: Allthefallen Booru A Cautionary Tale of Digital Scandal, Privacy Breaches, and the Ethics of Free Expression

Austin Reaves’ Playoff Performance: A Statistical Breakdown Why You Can No Longer Overlook Him