Aluminum 2020: The Dual Edge of Lightweight Excellence Shaping Modern Engineering

Aluminum 2020: The Dual Edge of Lightweight Excellence Shaping Modern Engineering

In an era defined by speed, efficiency, and sustainability, Aluminum 2020 emerges as a material that redefines what’s possible across industries—offering a rare balance of strength, formability, and recyclability. This certified aluminum alloy, part of the 200-series family with specific mechanical and chemical qualifications under ASTM A850, delivers performance unmatched by many heavier alternatives. With a tensile strength of approximately 265 MPa and exceptional corrosion resistance, Aluminum 2020 stands at the forefront of modern material innovation—proving that light does not mean weak.

Defined by precise composition and standardized testing, Aluminum 2020 is recognized for its consistent behavior in structural and industrial applications. Its chemistry includes copper as the primary alloying element—typically 0.4–0.8%—paired with magnesium, manganese, and chromium, yielding a material that resists stress corrosion cracking while maintaining excellent weldability. “Aluminum 2020 combines the best of both worlds: ductility for forming and strength for load-bearing,” notes Dr.

Elena Torres, materials scientist at the Center for Advanced Metals. “It’s engineered for real-world demands—where reliability meets precision.”

Among its most notable properties is a combination of moderate strength and excellent thermal conductivity, making it ideal for applications requiring efficient heat dissipation without sacrificing structural integrity. Its thermal conductivity of around 160 W/m·K supports use in heat exchangers and electronic enclosures, where thermal management is critical.

Additionally, its low density—approximately 2.7 g/cm³—contributes to weight savings across sectors, directly translating to fuel efficiency in transportation and reduced energy consumption in manufacturing.

Common applications span architectural cladding, automotive lightweighting, aerospace components, and consumer electronics. In building design, Aluminum 2020’s durability and aesthetic finish provide both functional and visual appeal—used extensively in curtain walls and window frames.

The automotive industry leverages its formability to create complex body parts that reduce vehicle weight without compromising crash safety. “Automakers are increasingly specifying Aluminum 2020 for structural panels and battery enclosures in electric vehicles,” explains engineers at MetalTech Innovations. “Its ability to withstand cyclic loads while being easily formed gives manufacturers a competitive edge in developing longer-range EVs.”

In aerospace, the alloy supports precision-critical components where weight reduction is paramount.

Components such as rivets, brackets, and interior structural parts utilize Aluminum 2020 not only for its strength-to-weight ratio but also for its compatibility with advanced manufacturing techniques like push-to-match forming. “Unlike higher-strength alloys that are brittle when cold-formed, 2020 maintains ductility down to sub-zero temperatures,” says metallurgist James Cho, whose work focuses on next-gen aerospace materials. “That reliability in extreme conditions is non-negotiable.”

Corrosion resistance is another hallmark: a natural oxide layer protects underlying aluminum from moisture and atmospheric degradation, reducing maintenance and extending service life.

This passive layer, combined with low galvanic potential, ensures compatibility with other metals in mixed-material assemblies—critical in both construction and industrial equipment. “This oxide isn’t just a surface feature—it’s active protection,” says Dr. Torres.

“In coastal installations and marine environments, 2020 outperforms untreated alternatives by decades.”

Innovations in processing have further unlocked Aluminum 2020’s potential. Recent advances in powder metallurgy and additive manufacturing enable complex geometries previously impractical. Direct metal laser sintering (DMLS) now produces optimized lattice structures that maximize strength while minimizing mass—used in medical implants, tooling, and high-performance sporting equipment.

“We’re moving beyond pure fabrication toward intelligent design,” explains Dr. Lila Mendez, a lead engineer at a metal 3D-printing startup. “Aluminum 2020’s formability and printability make it a cornerstone of the metal additive revolution.”

Sustainability amplifies Aluminum 2020’s value.

As one of the most recycled metals on Earth—with secondary production consuming up to 95% less energy than primary smelting—the alloy supports circular economy goals. Its long service life and recyclability position it as a strategic choice for industries aiming to reduce carbon footprints. “Every time Aluminum 2020 is recycled, it retains all its mechanical properties,” states the International Council for Aluminum Recycling (ICAR).

“This makes it not just a performance material, but a climate-aligned one.”

Despite its many strengths, Aluminum 2020 is not without limitations. It exhibits lower creep resistance than higher-temperature alloys and requires careful surface treatment to enhance paint adhesion. However, modern surface engineering—anodizing, chemical oxidation, and protective coatings—mitigates these issues effectively, preserving its core advantages.

As the demands on materials grow more exacting—driven by electrification, urban density, and environmental accountability—Aluminum 2020 continues to prove indispensable. Its engineered properties support innovation across sectors

Related Post

Deephotlink A Comprehensive Guide To Understanding Its Impact And Applications: Is This the Missing Link to Your 300% Growth?

Unveiling the World of Methstreamscx: A Deep Dive Into Its Features and Transformative Applications

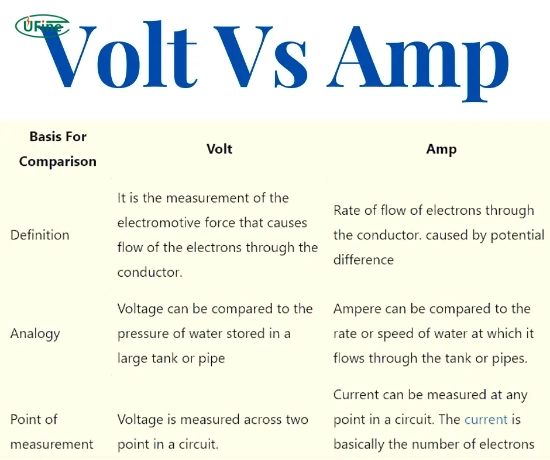

Differential Voltage: Definition, Applications, And More