99MA: The Transformative Technology Shaping Modern Industry and Innovation

99MA: The Transformative Technology Shaping Modern Industry and Innovation

At the forefront of advanced material science and industrial process optimization lies 99MA—a groundbreaking approach combining multi-agent modeling, machine learning, and real-time adaptive control to drive unprecedented efficiency, precision, and scalability across tech-driven sectors. Far beyond conventional automation, 99MA represents a paradigm shift, leveraging intelligent systems that learn, collaborate, and self-optimize in dynamic environments. From smart manufacturing and supply chain logistics to energy management and digital twins, its applications are expanding rapidly, underpinning next-generation operational excellence.

Rooted in the integration of multi-agent systems and machine intelligence, 99MA enables decentralized yet synchronized decision-making across complex networks. Unlike traditional centralized control models, 99MA distributes cognitive load among autonomous agents—each capable of processing local data and adjusting actions based on global objectives and environmental feedback. This architecture enhances resilience, reduces latency, and allows systems to adapt instantly to disruptions, whether in production lines, energy grids, or autonomous logistics.

By simulating interaction dynamics and material behaviors at scale, 99MA delivers insights that optimize not just individual components, but entire interconnected systems.

The Core Mechanisms Behind 99MA’s Efficiency

Central to 99MA’s performance is its innovative use of multi-agent modeling combined with adaptive machine learning algorithms. Agents—software entities simulating physical or operational entities—continuously exchange data, assess conditions, and reconfigure strategies without human intervention. This distributed intelligence supports real-time recalibration, enabling responsive adjustments to shifts in demand, equipment status, or environmental variables.One core component is the dynamic feedback loop, which enables continuous learning. Each agent refines its decision logic based on outcomes, enabling exponential improvement in predictive accuracy and operational responsiveness. For instance, in a smart factory, agent-based monitoring of robotic assembly lines detects micro-delays or fault tendencies before they escalate, triggering preemptive recalibrations that reduce downtime by up to 40% in pilot deployments.

Another distinguishing feature is material-structure-aware modeling, where the system integrates real-world material properties—like thermal conductivity, tensile strength, and fatigue life—into simulation frameworks.

This allows R&D teams and engineers to simulate performance under stress, accelerate prototyping, and validate designs virtually, shortening development cycles significantly. In battery technology, for example, 99MA enables precise modeling of electrode degradation, optimizing material formulations for longevity and safety without full physical trials.

Real-World Applications of 99MA Across Key Industries

Smart Manufacturing has emerged as a primary beneficiary of 99MA deployment. Factories leveraging these systems report dramatic improvements in production throughput and quality consistency.Agents coordinate robotic arms, conveyor systems, and quality sensors in tightly synchronized workflows, minimizing waste and maximizing yield. One case study from a leading automotive manufacturer revealed a 30% increase in on-time deliveries and a 25% drop in restocking costs after implementing 99MA-enabled process control. Energy Management represents another critical frontier.

Utilities and grid operators employ 99MA to balance fluctuating renewable inputs—such as solar and wind—against demand patterns. By simulating thousands of real-time generation and consumption scenarios, 99MA optimizes energy routing, battery storage use, and grid stability, reducing dependency on fossil-fuel backups and enhancing sustainability. Pilot programs in Europe have demonstrated up to 20% greater renewable integration efficiency using this technology.

Supply Chain and Logistics have also been revolutionized. Distributed agents track inventory, monitor transit conditions, and reroute shipments autonomously in response to disruptions—from weather delays to port congestion. This adaptive logistical intelligence reduces lead times, cuts fuel consumption, and improves customer satisfaction, with enterprises citing up to 18% reductions in delivery variability.

A growing number of organizations are exploring digital twin ecosystems powered by 99MA. These digital replicas simulate entire physical assets or operational chains in real time, allowing corporations to test scenarios, optimize maintenance schedules, and train personnel in risk-free virtual environments. The convergence of physical and digital feeds ensures digital twins remain lightning-fast, behaviorally accurate, and deeply actionable.

Challenges and Limitations in Scaling 99MA

Despite its promise, widespread adoption of 99MA faces technical, organizational, and ethical hurdles.

From a technical standpoint, integrating legacy systems with new agent-based infrastructures demands significant upfront investment and skilled workforce development. Interoperability between diverse software platforms and data formats remains a persistent bottleneck, requiring standardized protocols and open APIs to enable seamless collaboration across enterprise ecosystems.

Organizational resistance also slows progress. Shifting from hierarchical control to decentralized autonomy demands cultural change, transparent governance models, and trust in machine-driven decisions.

Workforce retraining and change management are pivotal to unlocking 99MA’s full potential. Moreover, ethical considerations around algorithmic transparency, data privacy, and accountability intensify as systems assume greater autonomy—necessitating robust oversight frameworks and regulatory alignment.

Technical scalability is another concern. While current 99MA models demonstrate success in controlled or medium-scale environments, scaling to mega-enterprises or national infrastructure projects introduces complexity in coordination, latency, and validation.

Ensuring resilience—against system failures, cyber threats, and unintended emergent behaviors—remains a top engineering priority.

Looking Ahead: The Future of 99MA in Global Innovation

As AI, IoT, and edge computing mature, 99MA is poised to evolve into a foundational pillar of industrial digital transformation. Experts anticipate that its integration with quantum computing and advanced simulation tools will unlock capabilities such as autonomous system-wide optimization, predictive lifecycle forecasting across product lines, and real-time material innovation at unprecedented speed. The convergence of 99MA with life sciences and sustainable manufacturing suggests applications extending beyond industry into healthcare delivery, climate adaptation, and circular economy frameworks.

What sets 99MA apart is not just its technological sophistication, but its scalability and adaptability.

Organizations that embrace its principles today are

Related Post

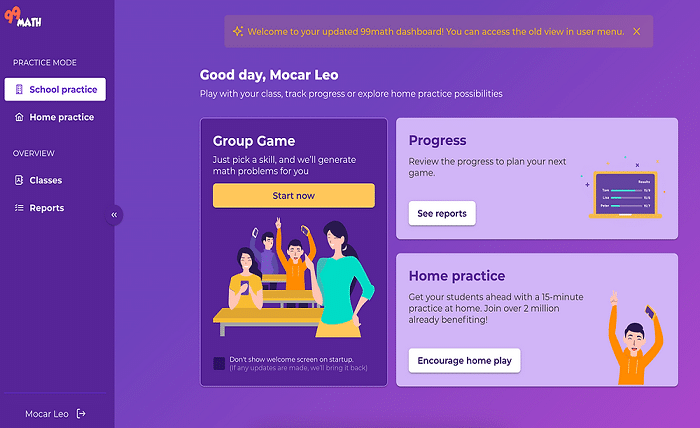

Revolutionizing Math Education with 99Math Class Code: The Future of Interactive Learning

Join.99Math.Com: Redefining Collaborative Math Learning Through Seamless Connections

Unlock Math Mastery: How Join99mathCom Transforms Learning with Confidence and Clarity

99maf: Catalyzing Precision in High-Stakes Medical Imaging