90radio: Your Ultimate Guide To Troubleshooting & Repair

Struggling with a malfunctioning appliance, a stalling vehicle, or a confused electrical system? 90Radio: Your Ultimate Guide to Troubleshooting & Repair provides a comprehensive, expert-backed roadmap to diagnosing and fixing common issues with confidence and precision. Whether you're a seasoned DIYer or a beginner tackling your first repair, this guide equips readers with proven methodologies, clear error identification steps, and practical diagnostic tools to restore function—fast and safely.

Why Systematic Troubleshooting Transforms Repair Success

> Troubleshooting isn’t just about trial and error—it’s a structured discipline that separates hasty fixes from lasting solutions.This guide emphasizes a step-by-step approach: observe, identify, isolate, and resolve. By following a proven sequence, users avoid common pitfalls like replacing functional parts or misdiagnosing symptoms. For example, a non-starting car engine may stem from a dead battery, faulty spark plug, or fuel delivery issue—each requiring distinct diagnostic moves.

“Jumping to conclusions wastes time and money,” notes automotive technician Mark Reynolds. “A disciplined troubleshooting process cuts guesswork and builds confidence.” The methodology outlined prioritizes logical progression over brute-force testing, turning overwhelming failures into manageable problems.

The Core Framework: Diagnose Before Repairing

> Every repair begins with diagnosis.The guide breaks the process into actionable phases:

- Observe Symptoms: Note unusual noises, warning lights, or performance drops. High readings from a multimeter or smoke from an engine can signal specific issues.

- Gather Information: Review manuals, check warranties, and inspect easy-access components—loose wires, worn belts, or fluid leaks often point to root causes.

- Isolate Systems or Components: Disconnect or disable parts incrementally to pinpoint where dysfunction begins.

- Verify Faults with Tools: Use diagnostic scanners, test lights, pressure gauges, and thermal imaging to validate hypotheses.

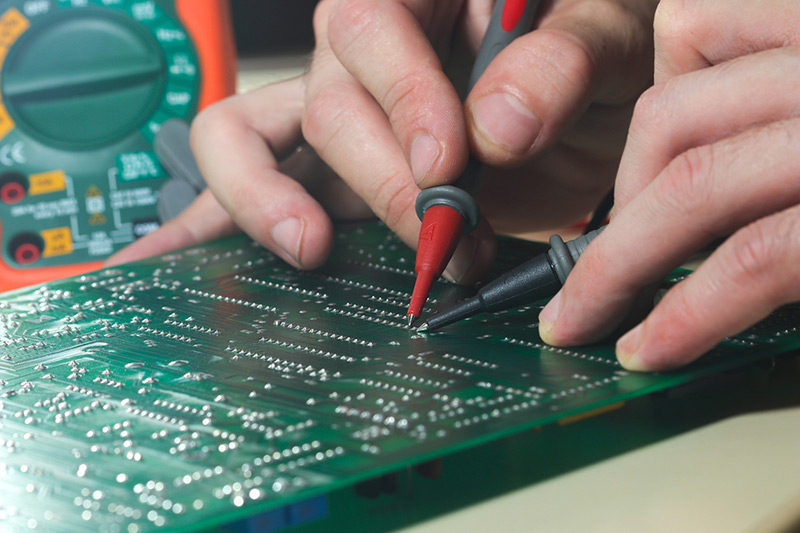

Electronics Troubleshooting: Decoding Modern Device Failures

> Electronics-based failures demand attention to power flow, signal integrity, and component health.From faulty smartphone charging circuits to broken home appliance boards, systematic diagnostics are essential.

- Start with Power and Connections: Must-test voltage at outlets and inspect fuses. Loose or corroded connectors often mimic software faults.

- Use Diagnostic Tools: Multimeters, oscilloscopes, and manufacturer-specific scan tools reveal hidden electrical anomalies.

- Test Components Under Load: A failing capacitor may work in isolation but fail when current demand increases—simulate real-world usage to trigger faults reliably.

- Review Firmware and Settings: A simple restart or reboot can resolve software glitches mimicking hardware failure.

Lena Park, “Modern devices are engineered with diagnostic layers built in—use capacitors, continuity testers, and thermal cameras to spot faults invisible to the naked eye.” This layer of technical insight elevates troubleshooting beyond guesswork into precision engineering.

Mechanical Systems: Diagnosing Engines, HVAC, and Moving Parts

> Mechanical failures—whether a grinding transmission, a leaking HVAC unit, or a seized bearing—require understanding force, flow, and wear patterns. The guide highlights mechanical-specific testing:- Inspect for Physical Damage: Look for bent shafts, torn belts, or distorted valve components under mechanical stress.

- Monitor Fluid and Pressure: Low hydraulic pressure, leaking oils, or air in compressed systems often reveal mechanical degradation.

- Perform Strain and Load Tests: Simulate normal operating conditions to observe performance under real stress—warm-ups, turning cycles, or pressure builds.

- Utilize Vibration and Thermal Analysis: Unbalanced rotating parts generate heat and vibration patterns diagnosable with specialized sensors.

This empirical approach ensures repairs align with actual mechanical health, not just surface-level symptoms.

Diagnostic Tools & Equipment: Your Technical Arsenal

> Owning the right tools turns troubleshooting from frustration into efficiency. The guide identifies essential instruments that bridge knowledge and hands-on action:- Multimeters: Essential for measuring voltage, current, resistance—critical for electrical circuits.

- Oscilloscopes and Signal Analyzers: Diagnose complex electronic malfunctions by observing waveform patterns.

- Thermal Cameras: Detect overheating hotspots in electrical panels, motors, or insulation gaps.

- Manufacturer-Specific Diagnostic Software: Monitors real-time system data, logs fault codes, and validates component behavior.

- Basic Hand Tools: Precision screwdrivers, torque wrenches, and insulated probes allow access and sensitive adjustments.

“A thermal camera will show a hot bearing, but knowing its ‘normal’ baseline temperature turns data into action,” notes service technician Ana Cruz.

Common Pitfalls—and How to Avoid Them

> Even experienced troubleshooters risk repeated errors. The guide highlights three frequent missteps:- Skipping the Basics: Ignoring simple fixes—tightening connectors, replacing fuses, or cleaning contacts—wastes time and risks reinfection of the problem.

- Over-Reliance on Guesswork: Assuming “that’s just a bad battery” without verifying with a test scan often leads to replacement errors.

Related Post

Bryan Duran Age Wiki Net worth Bio Height Girlfriend

Grayson Waller Sends Thirsty Tweet About Margot Robbie

Dissecting the Path of Makepeace, Chris in Modern Discussion

WWE RAW Results Coverage Reactions and Highlights for February 12 2024