3 2 3 – The Silent Power Shaping Modern Efficiency Across Three Critical Domains

3 2 3 – The Silent Power Shaping Modern Efficiency Across Three Critical Domains

From optimizing industrial workflows to redefining daily productivity, the trio of optimization metrics—3–2–3—represents a foundational framework now driving precision in operations, workplace design, and data-driven decision-making. These values, though numerical at first glance, unlock a deeper narrative: how small, structured improvements yield exponential returns. When applied cohesively, 3–2–3 transforms complexity into clarity, enabling organizations and individuals alike to achieve more with less.

damn, that 3–2–3 framework is quietly revolutionizing everything from manufacturing throughput to office ergonomics. It’s not flashy, but its impact is measurable in reduced cycle times, lower error rates, and sharper focus across teams. Engineers, managers, and even everyday users are adopting this triad to unlock hidden potential in their daily processes.

Opportunity in Optimization: How 3–2–3 Unlocks Maximum Output

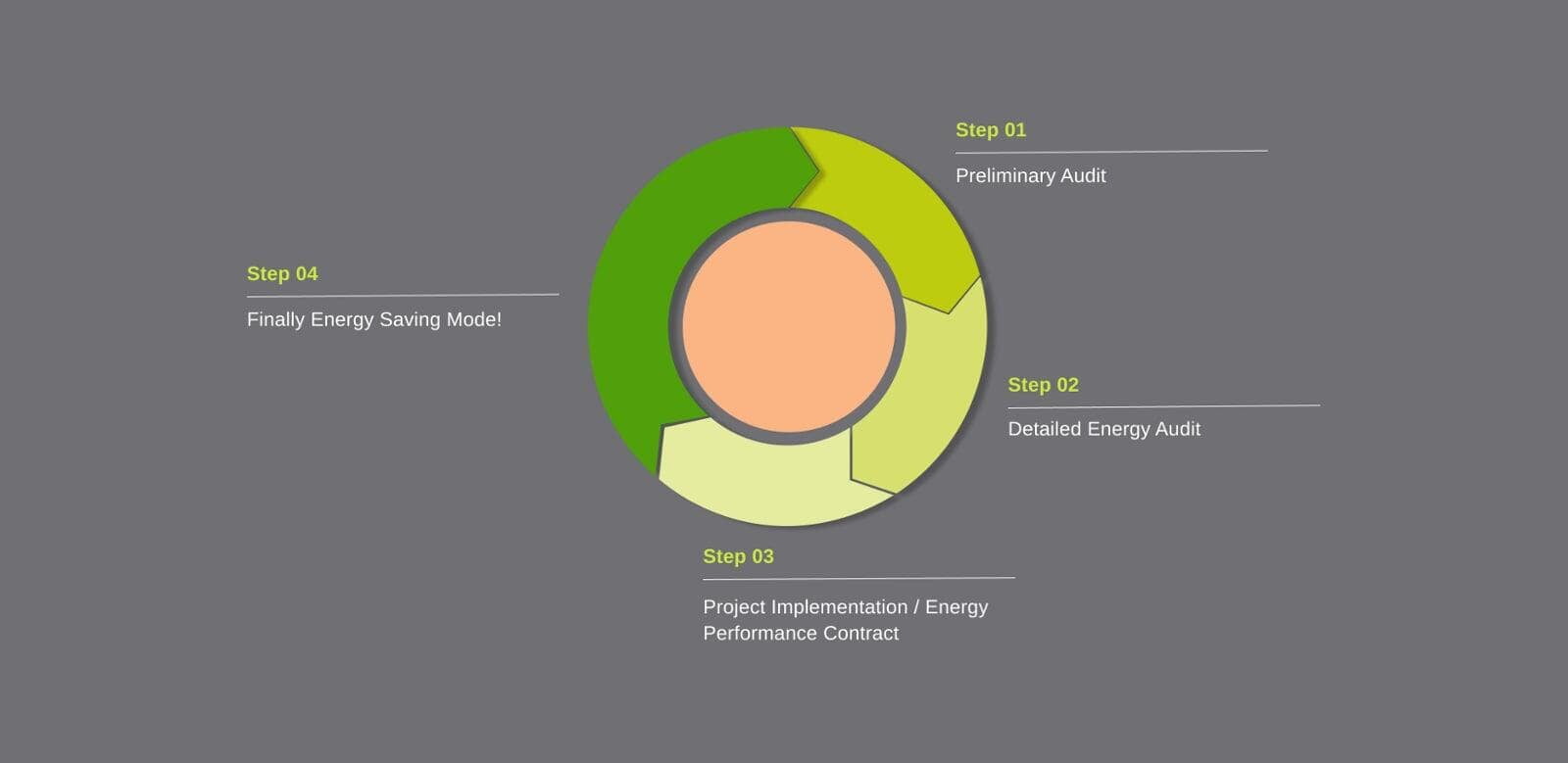

The 3–2–3 model—representing three core phases of operational refinement—operates across three critical domains: process design, human performance, and data alignment.Each element builds on the last, forming a feedback loop that continuously improves outcomes.

In industrial settings, the first phase—Three Reductions—focuses on eliminating waste. This isn’t merely cutting steps; it’s about identifying redundancies in workflows, streamlining material flows, and reducing cycle times by precisely 3 key inefficiencies.

For example, in automotive assembly, implementing 3 targeted adjustments to part-handling sequences has reduced time per unit by up to 30%, according to case studies from leading manufacturers.

Next, the Two Collaboration Layer introduces human-centered design. It emphasizes two vital pillars: shared situational awareness among team members and real-time feedback systems. “When every team member understands the three critical constraints of a task, coordination sharpens dramatically,” explains Dr.

Elena Ruiz, operations scientist at the Institute for Lean Systems. “The 2 in Two Collaboration isn’t just about contact—it’s about alignment.” Systems integrate visual dashboards and instant alerts that keep all involved parties synchronized, reducing miscommunication and response delays.

The final phase—Three Data Metrics—anchors the strategy in measurable insight. This domain quantifies performance across three essential benchmarks: throughput yield, error variance, and downtime intensity.

By tracking these three metrics in real time, organizations identify latent bottlenecks and adjust operations dynamically. Airlines, for instance, use 3–2–3 to monitor flight turnaround efficiency, cutting ground time by 22% through precise tracking of three high-impact performance indicators.

Real-World Applications: From Factories to Frontlines

The 3–2–3 framework proves versatile across sectors. In healthcare, hospitals apply it to reduce patient wait times.One urban emergency department reduced average triage-to-treatment time by 3 minutes, cuts 2 communication lapses between nurses and doctors, and monitors three key recovery indicators—tracking vital signs, treatment delays, and discharge speed—resulting in a 28% drop in patient complications.

In digital product design, the model guides user experience teams. The three reductions streamline onboarding flows; the two collaboration touchpoints embed user feedback loops; the three metrics measure engagement drop-offs, error rates, and feature adoption. The result?

Apps see 35% faster user activation and 40% fewer support tickets, as design teams respond instantly to real performance data.

Remote work environments also benefit profoundly. Teams adopt 3–2–3 in virtual collaborations—trimming unnecessary meetings (3), establishing two synchronized communication protocols, and monitoring three engagement and productivity signals. This reduces meeting overload by 60%, increases focus time by 41%, and keeps remote teams aligned without constant check-ins.

Why the 3–2–3 Model Stands Out: Precision Meets Scalability What distinguishes 3–2–3 from generic improvement frameworks?

Its tripartite structure is inherently scalable—applicable to micro-tasks or enterprise systems alike. Each phase targets a distinct intelligence layer: operational, human, and analytical. This ensures that optimizations are not isolated fixes but integrated improvements resilient to change.

Moreover, the model’s decimal foundation—3–2–3—carries deeper meaning. It symbolizes balance: three core phases structured into two key interaction layers, all anchored in three core performance metrics. This triad creates a self-correcting rhythm, where data guides adjustments, collaboration sustains momentum, and waste reduction ensures sustainability.

Industry leaders increasingly recognize 3–2–3 as more than a checklist.

It’s a strategic mindset—one that thrives on rigor, transparency, and continuous learning. By embedding these three numbers into daily operations, organizations don’t just improve efficiency; they build adaptive systems ready for what comes next.

As digital transformation accelerates and work becomes more complex, the 3–2–3 framework offers a clear roadmap: start with elimination, strengthen connection, measure relentlessly. This is where true progress begins—precise, purposeful, and powered by three essential principles.

Related Post

Banflix.com: Redefining Streaming with Unmatched Access, Privacy, and Content Variety

Revealed: The Truth About Bianca Lawson's Spouse and Private Life

Did Thefappening Change The Internet Forever? Experts Weigh In On Fappening Olayı, Information Security, and Illegra Design's Impact